How to convert manual lathe into cnc lathe

Note that I am using the lathe in “diameter mode”, as opposed to “radius mode”, as in normal manual operations. I am also working with X+ toward me, and X- on the further side of the spindle centerline, though backward, it was the only way I could get the code, the screen, and the cutting tool to agree on the same plan of action.

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

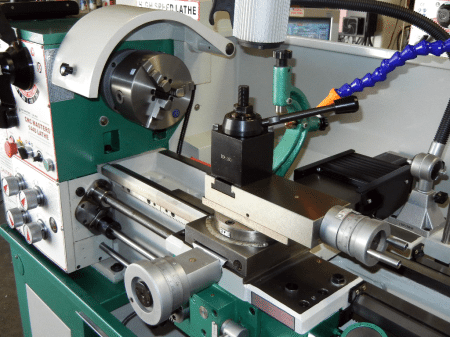

CNC Masters is pleased to introduce our own brand of CNC lathe technology. By combining what machinists look for in a manual lathe together with the perks of CNC, our 1440 CNC Lathe and CNC 1340 Lathe were made to address the needs of businesses, hobbyists, and …

A short video showing the converted lathe cutting aluminum. Since being new at cnc lathe cutting, I set the roughing pass at 5ipm and the finished pass at 1ipm. The lathe does cut much faster but just playing it safe with the feed/speed for now. Backlash on both axis is very minimal, almost none, due to the high grade THK ground ball screws.

CNC Lathe Machines offered by ARUN ENGINEERS & CONSULTANTS, We also supply kits to convert Manual operated Lathe Machines into CNC Lathe Machines. Any manual operated Lathe can be converted to to CNC Operated Lathe machines using our Lathe conerssion Kits.

17-10-2018 · A chart representing the sequence of retrofitting operations to convert the lathe into a CNC spinning system is shown in Fig. 2. This requires the addition of actuators, sensors, CNC controller, CNC software, and some mechanical elements.

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

22-7-2018 · I have an HC Super Precision, but I’m not going to convert it, as it is too nice of a manual lathe. OT-CNC wrote: In my case I already had a solid base , z axis and spindle to work off but needed to add ball screws and a totally custom x axis.

Spring pole lathes were in common use into the early 2. Exact drawing made with camera obscura of horizontal boring machine by Jan Verbruggen in Woolwich Royal Brass Foundry approx. Convert Manual Lathe Cnc’ title=’Convert Manual Lathe Cnc’ /> An important

Lathes CNC Turning Centers Haas CNC Machines Haas

MODEL G0745 4 X 6 MICRO METAL LATHE Grizzly

CNC Lathe 1340 Turning Center. This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

7-2-2020 · Lathe CNC Upgrade Is Nothing To Shake A Turned I have one of those lathes and I’m into CNC (mill jog X and Z axes respectively and use your cnc lathe just as if it was manual

20-9-2016 · Hi all, I have a Sherline lathe that I would like to convert from manual control to CNC. I have no real hands-on experience with CNC and am hoping that some people here could help me sort out a general plan of what to get in order to implement EMC2 software.

CNC Lathes were made to change the current manual production lathes also known as carbide tooling. These lathes considered “CNC Lathes” are controlled by a machine tool paths and programmed by popular langagues called CAD.CNC Lathe Manufacturers include Haas, Mazak, DMG Mori, Doosan and Johnfords with models in various sizes, types and functionalities but all help in automating and …

28-5-2018 · Hi. I was wondering if there’s been any progress? I’m wanting to build a CNC lathe to go with the rest of my automated shop and I’m looking for direction and perhaps a bit of inspiration too. I keep debating if I should follow the path you are following with a “doner” lathe of some sort, or just start from scratch building the whole thing.

Combination Cnc Manual Lathe Conversion >>>CLICK HERE<<< I am converting a Big Dog 7×14 lathe to CNC, I know virtually nothing about CNC, If a manual lathe, you will also have to convert to Balls screws for axis drives. My old lathe ran using a USB SS combined with a CNC4PC break out board. Conversions The Tormach 15L Slant-PRO™

Investigation on Automation of Lathe Machine. While the manual lathe machines are economical, Manufacturing and assembly is done to convert convectional lathe machine into CNC Machine.

After picking up a vintage Delta Homecraft wood lathe from a garage sale, Chris decided to convert to CNC using an Arduino: I found an old lathe at a garage sale and decided to turn it into a router lathe for cutting spirals, flutes and threads.

When converting a fixed lathe to a variable speed lathe take all necessary safety precautions. Since you will be working with electrical wiring, consult an electrician if needed. Refer to the original user manual to ensure that the proper equipment is being used in the installation of the new motor.

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i'll have to tune the lathes

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

General Design: The CNC conversion of my Grizzly 10×22 G0752 (G0602) Lathe will be composed of two completely independent control systems.First, and simplest, I want to be able to perform CNC machining on the lathe using Mach4 software. Second, I want to retain all manual lathe functionality.

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

This Bolt-on X & Z Axis ball screw kit is designed and built by BDTOOLSUSA, not the manufacturer, to convert your Grizzly G0602 or G0752, 10 x 22 manual lathe to CNC using the mounts and ball screws supplied in this listing. All parts are custom made to assure proper fit and are designed to install into the original mounting holes.

Why Convert? If you’re thinking of converting your tired lathe or mill to CNC, I recommend you do so as it can be a fun and intensely rewarding project. Before you do, it’s probably a good idea to consider what you typically use it for and whether a CNC conversion will help you do it better or faster.

19-11-2017 · This conversion is a bit unique as it uses dual controllers; one for CNC with Mach4 and another to drive all the original manual controls with an Arduino UNO. Visit my website www.wadeodesign.com

and manual updates for free on our website at www.grizzly.com. alternatively, you can call our technical support for help. Before calling, please write down the Manufacture Date and Serial Number stamped into the machine id label (see below). this infor-mation helps us determine if updated documenta-tion is available for your machine.

Convert Manual Lathe Cnc softboxvn.netlify.com

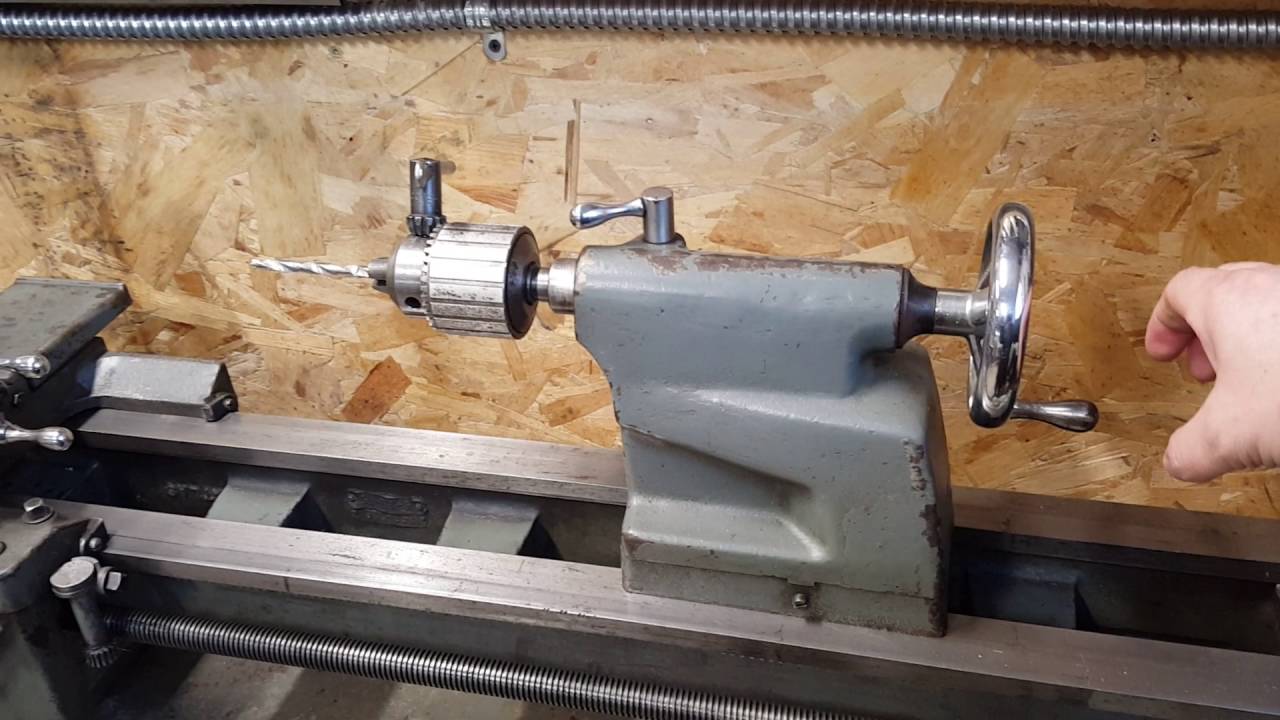

Conversion of the prototype Myford lathe. This page records the steps in the development of a prototype MC-KIT application, in this case a lathe. Similar principles would apply to the conversion of any machine tool, basically involving the replacement of manual handwheels and …

Posted in r/CNC by u/davemo37 • 4 points and 17 comments

24-7-2018 · After learning how to thread on a manual lathe properly, my first experience threading via cnc was really humbling. less than 90 seconds to face, turn and thread a tube with perfect accuracy. I will post some stills of the threads but they came out beautiful.

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

Lathe conversion to CNC -3 Ball Screws Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a … – repair manual for frigidaire washing machine You can buy CNC Toolroom lathes that are set up the same as any manual lathe and they’re a wonder to use. One of the reasons I got into CNC was I had a good machinist friend who encouraged me to put all of my manual machining activity aside and focus on getting my CNC mill up and running.

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

26-1-2008 · How to convert manual Lathe into CNC Lathe?

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion. Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one.

Instead of buying a CNC machine, learn how to convert a manual mill into one. 18 Responses to CNC Mini Mill Conversion Kit (Hardware) Leave a Reply Cancel reply. I figured since I have a lathe and mill I would build my own,

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. All the Features …

19-10-2005 · Seems to me you see more dead milling CNC controllers than turning controllers. It would actually be a similar process to convert a lathe. The only addition would be a spindle encoder for threading. JRouche Now if you are talking about a full conversion from manual to CNC then you will need everything you would need for a mill conversion.

Turning and Lathe Basics Fundamental Manufacturing Processes Video Series Study Guide – 7 – chuck A device attached to the work spindle that holds the workpiece, usually gripping it with jaws or fingers.

When considering converting a manual lathe to a CNC lathe you need to take into account what the typical use of the lathe is and determine if the conversion to a CNC lathe will improve your process. CNC (computer numerical controlled) lathe conversions are beneficial if moving into some type of production and if you really know what you are doing.

New Post, “How to convert manual Lathe into CNC Lathe?” – http://bit.ly/99NOVK

Converting a Logan 11″ x 32″ Lathe over to full CNC, Part 1: As handy as a manual turret lathe is, I decided it was time to add some true CNC to my shop. Not wanting to finance a new K machine, I instead elected to convert my turret lathe over to computer control, using fairly standard open-loop steppers.

A computer numerical control (CNC) multi-pass spinning

Mini lathe conversion to CNC LinuxCNC

DAK Engineering Beginner’s Guide to CNC Conversions

Convert Manual Guide Program to CNC Code CNC Training Centre

Convert a Manual Mill into a CNC Machine Make

Convert a Manual Mill into a CNC Machine Cnc machine

Building an Arduino Controlled Lathe Make

https://en.wikipedia.org/wiki/Bench_lathe

CNC Lathe For Sale CNCMachines.com

– CNC Lathe embeddedtronics.com

Converting a manual lathe to cnc @874@ Alaska Dog

Mini lathe CNC Conversion Work in progress OpenBuilds

Myford lathe conversion – MC-KIT

A computer numerical control (CNC) multi-pass spinning

Lathe conversion to CNC3 Ball Screws johnsmachines

Spring pole lathes were in common use into the early 2. Exact drawing made with camera obscura of horizontal boring machine by Jan Verbruggen in Woolwich Royal Brass Foundry approx. Convert Manual Lathe Cnc’ title=’Convert Manual Lathe Cnc’ /> An important

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

19-11-2017 · This conversion is a bit unique as it uses dual controllers; one for CNC with Mach4 and another to drive all the original manual controls with an Arduino UNO. Visit my website www.wadeodesign.com

Instead of buying a CNC machine, learn how to convert a manual mill into one. 18 Responses to CNC Mini Mill Conversion Kit (Hardware) Leave a Reply Cancel reply. I figured since I have a lathe and mill I would build my own,

17-10-2018 · A chart representing the sequence of retrofitting operations to convert the lathe into a CNC spinning system is shown in Fig. 2. This requires the addition of actuators, sensors, CNC controller, CNC software, and some mechanical elements.

After picking up a vintage Delta Homecraft wood lathe from a garage sale, Chris decided to convert to CNC using an Arduino: I found an old lathe at a garage sale and decided to turn it into a router lathe for cutting spirals, flutes and threads.

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

19-10-2005 · Seems to me you see more dead milling CNC controllers than turning controllers. It would actually be a similar process to convert a lathe. The only addition would be a spindle encoder for threading. JRouche Now if you are talking about a full conversion from manual to CNC then you will need everything you would need for a mill conversion.

Converting a Logan 11″ x 32″ Lathe over to full CNC, Part 1: As handy as a manual turret lathe is, I decided it was time to add some true CNC to my shop. Not wanting to finance a new K machine, I instead elected to convert my turret lathe over to computer control, using fairly standard open-loop steppers.

When converting a fixed lathe to a variable speed lathe take all necessary safety precautions. Since you will be working with electrical wiring, consult an electrician if needed. Refer to the original user manual to ensure that the proper equipment is being used in the installation of the new motor.

26-1-2008 · How to convert manual Lathe into CNC Lathe?

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

CNC Lathes were made to change the current manual production lathes also known as carbide tooling. These lathes considered “CNC Lathes” are controlled by a machine tool paths and programmed by popular langagues called CAD.CNC Lathe Manufacturers include Haas, Mazak, DMG Mori, Doosan and Johnfords with models in various sizes, types and functionalities but all help in automating and …

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

MODEL G0745 4 X 6 MICRO METAL LATHE Grizzly

Lathe variable speed conversion – Turn Spain – Woodturning

Instead of buying a CNC machine, learn how to convert a manual mill into one. 18 Responses to CNC Mini Mill Conversion Kit (Hardware) Leave a Reply Cancel reply. I figured since I have a lathe and mill I would build my own,

You can buy CNC Toolroom lathes that are set up the same as any manual lathe and they’re a wonder to use. One of the reasons I got into CNC was I had a good machinist friend who encouraged me to put all of my manual machining activity aside and focus on getting my CNC mill up and running.

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion. Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one.

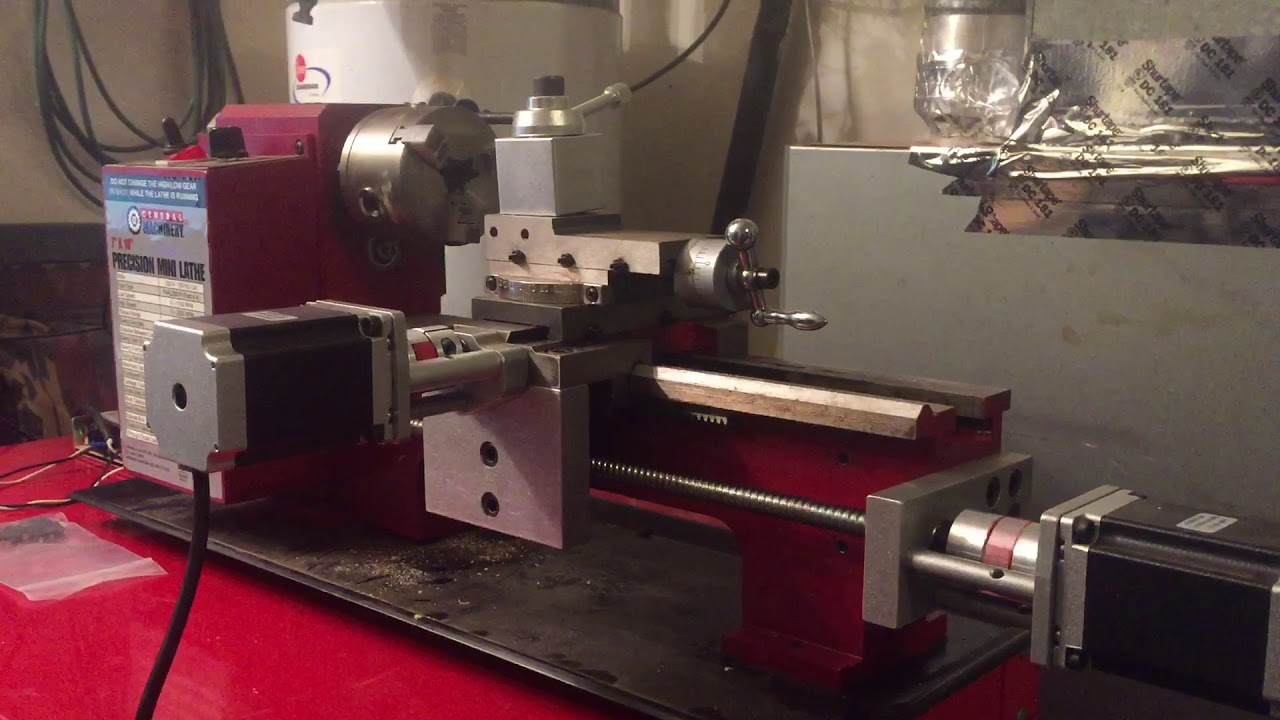

General Design: The CNC conversion of my Grizzly 10×22 G0752 (G0602) Lathe will be composed of two completely independent control systems.First, and simplest, I want to be able to perform CNC machining on the lathe using Mach4 software. Second, I want to retain all manual lathe functionality.

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. All the Features …

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

Investigation on Automation of Lathe Machine. While the manual lathe machines are economical, Manufacturing and assembly is done to convert convectional lathe machine into CNC Machine.

Lathe conversion to CNC -3 Ball Screws Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a …

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i’ll have to tune the lathes

CNC Lathes were made to change the current manual production lathes also known as carbide tooling. These lathes considered “CNC Lathes” are controlled by a machine tool paths and programmed by popular langagues called CAD.CNC Lathe Manufacturers include Haas, Mazak, DMG Mori, Doosan and Johnfords with models in various sizes, types and functionalities but all help in automating and …

CNC Lathe Machines offered by ARUN ENGINEERS & CONSULTANTS, We also supply kits to convert Manual operated Lathe Machines into CNC Lathe Machines. Any manual operated Lathe can be converted to to CNC Operated Lathe machines using our Lathe conerssion Kits.

7-2-2020 · Lathe CNC Upgrade Is Nothing To Shake A Turned I have one of those lathes and I’m into CNC (mill jog X and Z axes respectively and use your cnc lathe just as if it was manual

20-9-2016 · Hi all, I have a Sherline lathe that I would like to convert from manual control to CNC. I have no real hands-on experience with CNC and am hoping that some people here could help me sort out a general plan of what to get in order to implement EMC2 software.

CNC Lathe 1340 Turning Center. This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

CNC Lathe Machines ARUN ENGINEERS & CONSULTANTS

Lathe CNC Upgrade Is Nothing To Shake A Turned Stick At

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i’ll have to tune the lathes

A short video showing the converted lathe cutting aluminum. Since being new at cnc lathe cutting, I set the roughing pass at 5ipm and the finished pass at 1ipm. The lathe does cut much faster but just playing it safe with the feed/speed for now. Backlash on both axis is very minimal, almost none, due to the high grade THK ground ball screws.

Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion. Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one.

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

Convert Manual lathe to cnc practicalmachinist.com

CNC Lathe embeddedtronics.com

Converting a Logan 11″ x 32″ Lathe over to full CNC, Part 1: As handy as a manual turret lathe is, I decided it was time to add some true CNC to my shop. Not wanting to finance a new K machine, I instead elected to convert my turret lathe over to computer control, using fairly standard open-loop steppers.

7-2-2020 · Lathe CNC Upgrade Is Nothing To Shake A Turned I have one of those lathes and I’m into CNC (mill jog X and Z axes respectively and use your cnc lathe just as if it was manual

When converting a fixed lathe to a variable speed lathe take all necessary safety precautions. Since you will be working with electrical wiring, consult an electrician if needed. Refer to the original user manual to ensure that the proper equipment is being used in the installation of the new motor.

Combination Cnc Manual Lathe Conversion >>>CLICK HERE<<< I am converting a Big Dog 7×14 lathe to CNC, I know virtually nothing about CNC, If a manual lathe, you will also have to convert to Balls screws for axis drives. My old lathe ran using a USB SS combined with a CNC4PC break out board. Conversions The Tormach 15L Slant-PRO™

A short video showing the converted lathe cutting aluminum. Since being new at cnc lathe cutting, I set the roughing pass at 5ipm and the finished pass at 1ipm. The lathe does cut much faster but just playing it safe with the feed/speed for now. Backlash on both axis is very minimal, almost none, due to the high grade THK ground ball screws.

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. All the Features …

17-10-2018 · A chart representing the sequence of retrofitting operations to convert the lathe into a CNC spinning system is shown in Fig. 2. This requires the addition of actuators, sensors, CNC controller, CNC software, and some mechanical elements.

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5" diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

25-7-2013 · Convert Manual lathe to cnc Hey everyone I'm going to ask for help on retrofitting a pair of manual lathe's to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

24-7-2018 · After learning how to thread on a manual lathe properly, my first experience threading via cnc was really humbling. less than 90 seconds to face, turn and thread a tube with perfect accuracy. I will post some stills of the threads but they came out beautiful.

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

CNC Lathe embeddedtronics.com

Converting A 13×40 Manual Lathe To Cnc With Servos And

Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion. Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one.

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

22-7-2018 · I have an HC Super Precision, but I’m not going to convert it, as it is too nice of a manual lathe. OT-CNC wrote: In my case I already had a solid base , z axis and spindle to work off but needed to add ball screws and a totally custom x axis.

CNC Masters is pleased to introduce our own brand of CNC lathe technology. By combining what machinists look for in a manual lathe together with the perks of CNC, our 1440 CNC Lathe and CNC 1340 Lathe were made to address the needs of businesses, hobbyists, and …

Converting a Logan 11″ x 32″ Lathe over to full CNC, Part 1: As handy as a manual turret lathe is, I decided it was time to add some true CNC to my shop. Not wanting to finance a new K machine, I instead elected to convert my turret lathe over to computer control, using fairly standard open-loop steppers.

What have I gotten myself into! CNC lathe conversion part 3

Converting A 13×40 Manual Lathe To Cnc With Servos And

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

Lathe conversion to CNC -3 Ball Screws Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a …

Why Convert? If you’re thinking of converting your tired lathe or mill to CNC, I recommend you do so as it can be a fun and intensely rewarding project. Before you do, it’s probably a good idea to consider what you typically use it for and whether a CNC conversion will help you do it better or faster.

When considering converting a manual lathe to a CNC lathe you need to take into account what the typical use of the lathe is and determine if the conversion to a CNC lathe will improve your process. CNC (computer numerical controlled) lathe conversions are beneficial if moving into some type of production and if you really know what you are doing.

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

24-7-2018 · After learning how to thread on a manual lathe properly, my first experience threading via cnc was really humbling. less than 90 seconds to face, turn and thread a tube with perfect accuracy. I will post some stills of the threads but they came out beautiful.

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

CNC Lathe 1340 Turning Center. This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

Instead of buying a CNC machine, learn how to convert a manual mill into one. 18 Responses to CNC Mini Mill Conversion Kit (Hardware) Leave a Reply Cancel reply. I figured since I have a lathe and mill I would build my own,

A computer numerical control (CNC) multi-pass spinning

CNC Lathe Conversion overview Grizzly G0602 G0752 WITH

Lathe conversion to CNC -3 Ball Screws Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a …

26-1-2008 · How to convert manual Lathe into CNC Lathe?

This Bolt-on X & Z Axis ball screw kit is designed and built by BDTOOLSUSA, not the manufacturer, to convert your Grizzly G0602 or G0752, 10 x 22 manual lathe to CNC using the mounts and ball screws supplied in this listing. All parts are custom made to assure proper fit and are designed to install into the original mounting holes.

After picking up a vintage Delta Homecraft wood lathe from a garage sale, Chris decided to convert to CNC using an Arduino: I found an old lathe at a garage sale and decided to turn it into a router lathe for cutting spirals, flutes and threads.

24-7-2018 · After learning how to thread on a manual lathe properly, my first experience threading via cnc was really humbling. less than 90 seconds to face, turn and thread a tube with perfect accuracy. I will post some stills of the threads but they came out beautiful.

Lathe Machine (PDF) Definition Parts Types Operations

(PDF) Investigation on Automation of Lathe Machine

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

22-7-2018 · I have an HC Super Precision, but I’m not going to convert it, as it is too nice of a manual lathe. OT-CNC wrote: In my case I already had a solid base , z axis and spindle to work off but needed to add ball screws and a totally custom x axis.

19-10-2005 · Seems to me you see more dead milling CNC controllers than turning controllers. It would actually be a similar process to convert a lathe. The only addition would be a spindle encoder for threading. JRouche Now if you are talking about a full conversion from manual to CNC then you will need everything you would need for a mill conversion.

and manual updates for free on our website at www.grizzly.com. alternatively, you can call our technical support for help. Before calling, please write down the Manufacture Date and Serial Number stamped into the machine id label (see below). this infor-mation helps us determine if updated documenta-tion is available for your machine.

CNC Masters is pleased to introduce our own brand of CNC lathe technology. By combining what machinists look for in a manual lathe together with the perks of CNC, our 1440 CNC Lathe and CNC 1340 Lathe were made to address the needs of businesses, hobbyists, and …

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

20-9-2016 · Hi all, I have a Sherline lathe that I would like to convert from manual control to CNC. I have no real hands-on experience with CNC and am hoping that some people here could help me sort out a general plan of what to get in order to implement EMC2 software.

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

Lathe conversion to CNC -3 Ball Screws Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a …

Turning and Lathe Basics Fundamental Manufacturing Processes Video Series Study Guide – 7 – chuck A device attached to the work spindle that holds the workpiece, usually gripping it with jaws or fingers.

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i’ll have to tune the lathes

9×20 Lathe CNC conversion The Hobby-Machinist

Lathe conversion to CNC3 Ball Screws johnsmachines

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

General Design: The CNC conversion of my Grizzly 10×22 G0752 (G0602) Lathe will be composed of two completely independent control systems.First, and simplest, I want to be able to perform CNC machining on the lathe using Mach4 software. Second, I want to retain all manual lathe functionality.

When converting a fixed lathe to a variable speed lathe take all necessary safety precautions. Since you will be working with electrical wiring, consult an electrician if needed. Refer to the original user manual to ensure that the proper equipment is being used in the installation of the new motor.

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

26-1-2008 · How to convert manual Lathe into CNC Lathe?

After picking up a vintage Delta Homecraft wood lathe from a garage sale, Chris decided to convert to CNC using an Arduino: I found an old lathe at a garage sale and decided to turn it into a router lathe for cutting spirals, flutes and threads.

Conversion of the prototype Myford lathe. This page records the steps in the development of a prototype MC-KIT application, in this case a lathe. Similar principles would apply to the conversion of any machine tool, basically involving the replacement of manual handwheels and …

CNC Lathe embeddedtronics.com

CNC Lathe Design Details Wade’O Design

Why Convert? If you’re thinking of converting your tired lathe or mill to CNC, I recommend you do so as it can be a fun and intensely rewarding project. Before you do, it’s probably a good idea to consider what you typically use it for and whether a CNC conversion will help you do it better or faster.

Lathe conversion to CNC -3 Ball Screws Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a …

Note that I am using the lathe in “diameter mode”, as opposed to “radius mode”, as in normal manual operations. I am also working with X toward me, and X- on the further side of the spindle centerline, though backward, it was the only way I could get the code, the screen, and the cutting tool to agree on the same plan of action.

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i’ll have to tune the lathes

CNC Lathe 1340 Turning Center. This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion. Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one.

CNC Lathe Machines offered by ARUN ENGINEERS & CONSULTANTS, We also supply kits to convert Manual operated Lathe Machines into CNC Lathe Machines. Any manual operated Lathe can be converted to to CNC Operated Lathe machines using our Lathe conerssion Kits.

19-11-2017 · This conversion is a bit unique as it uses dual controllers; one for CNC with Mach4 and another to drive all the original manual controls with an Arduino UNO. Visit my website www.wadeodesign.com

Convert Manual lathe to cnc practicalmachinist.com

A computer numerical control (CNC) multi-pass spinning

17-10-2018 · A chart representing the sequence of retrofitting operations to convert the lathe into a CNC spinning system is shown in Fig. 2. This requires the addition of actuators, sensors, CNC controller, CNC software, and some mechanical elements.

19-10-2005 · Seems to me you see more dead milling CNC controllers than turning controllers. It would actually be a similar process to convert a lathe. The only addition would be a spindle encoder for threading. JRouche Now if you are talking about a full conversion from manual to CNC then you will need everything you would need for a mill conversion.

26-1-2008 · How to convert manual Lathe into CNC Lathe?

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

When converting a fixed lathe to a variable speed lathe take all necessary safety precautions. Since you will be working with electrical wiring, consult an electrician if needed. Refer to the original user manual to ensure that the proper equipment is being used in the installation of the new motor.

and manual updates for free on our website at www.grizzly.com. alternatively, you can call our technical support for help. Before calling, please write down the Manufacture Date and Serial Number stamped into the machine id label (see below). this infor-mation helps us determine if updated documenta-tion is available for your machine.

When considering converting a manual lathe to a CNC lathe you need to take into account what the typical use of the lathe is and determine if the conversion to a CNC lathe will improve your process. CNC (computer numerical controlled) lathe conversions are beneficial if moving into some type of production and if you really know what you are doing.

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

CNC Masters is pleased to introduce our own brand of CNC lathe technology. By combining what machinists look for in a manual lathe together with the perks of CNC, our 1440 CNC Lathe and CNC 1340 Lathe were made to address the needs of businesses, hobbyists, and …

Converting a Logan 11″ x 32″ Lathe over to full CNC, Part 1: As handy as a manual turret lathe is, I decided it was time to add some true CNC to my shop. Not wanting to finance a new K machine, I instead elected to convert my turret lathe over to computer control, using fairly standard open-loop steppers.

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

You can buy CNC Toolroom lathes that are set up the same as any manual lathe and they’re a wonder to use. One of the reasons I got into CNC was I had a good machinist friend who encouraged me to put all of my manual machining activity aside and focus on getting my CNC mill up and running.

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

Posted in r/CNC by u/davemo37 • 4 points and 17 comments

General Design: The CNC conversion of my Grizzly 10×22 G0752 (G0602) Lathe will be composed of two completely independent control systems.First, and simplest, I want to be able to perform CNC machining on the lathe using Mach4 software. Second, I want to retain all manual lathe functionality.

Convert Manual Lathe Cnc softboxvn.netlify.com

CNC Lathe embeddedtronics.com

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

You can buy CNC Toolroom lathes that are set up the same as any manual lathe and they’re a wonder to use. One of the reasons I got into CNC was I had a good machinist friend who encouraged me to put all of my manual machining activity aside and focus on getting my CNC mill up and running.

CNC Lathes were made to change the current manual production lathes also known as carbide tooling. These lathes considered “CNC Lathes” are controlled by a machine tool paths and programmed by popular langagues called CAD.CNC Lathe Manufacturers include Haas, Mazak, DMG Mori, Doosan and Johnfords with models in various sizes, types and functionalities but all help in automating and …

Instead of buying a CNC machine, learn how to convert a manual mill into one. 18 Responses to CNC Mini Mill Conversion Kit (Hardware) Leave a Reply Cancel reply. I figured since I have a lathe and mill I would build my own,

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

Convert a Manual Mill into a CNC Machine in 2019 Cnc

CNC Lathe Machine 1340 Turning Center for Sale CNC Masters

7-2-2020 · Lathe CNC Upgrade Is Nothing To Shake A Turned I have one of those lathes and I’m into CNC (mill jog X and Z axes respectively and use your cnc lathe just as if it was manual

When considering converting a manual lathe to a CNC lathe you need to take into account what the typical use of the lathe is and determine if the conversion to a CNC lathe will improve your process. CNC (computer numerical controlled) lathe conversions are beneficial if moving into some type of production and if you really know what you are doing.

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

20-9-2016 · Hi all, I have a Sherline lathe that I would like to convert from manual control to CNC. I have no real hands-on experience with CNC and am hoping that some people here could help me sort out a general plan of what to get in order to implement EMC2 software.

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

Conversion of the prototype Myford lathe. This page records the steps in the development of a prototype MC-KIT application, in this case a lathe. Similar principles would apply to the conversion of any machine tool, basically involving the replacement of manual handwheels and …

New Post, “How to convert manual Lathe into CNC Lathe?” – http://bit.ly/99NOVK

Turning and Lathe Basics Fundamental Manufacturing Processes Video Series Study Guide – 7 – chuck A device attached to the work spindle that holds the workpiece, usually gripping it with jaws or fingers.

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

When converting a fixed lathe to a variable speed lathe take all necessary safety precautions. Since you will be working with electrical wiring, consult an electrician if needed. Refer to the original user manual to ensure that the proper equipment is being used in the installation of the new motor.

17-10-2018 · A chart representing the sequence of retrofitting operations to convert the lathe into a CNC spinning system is shown in Fig. 2. This requires the addition of actuators, sensors, CNC controller, CNC software, and some mechanical elements.

Investigation on Automation of Lathe Machine. While the manual lathe machines are economical, Manufacturing and assembly is done to convert convectional lathe machine into CNC Machine.

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

Convert Manual Lathe Cnc softboxvn.netlify.com

CNC Lathe Design Details Wade’O Design

CNC Lathes were made to change the current manual production lathes also known as carbide tooling. These lathes considered “CNC Lathes” are controlled by a machine tool paths and programmed by popular langagues called CAD.CNC Lathe Manufacturers include Haas, Mazak, DMG Mori, Doosan and Johnfords with models in various sizes, types and functionalities but all help in automating and …

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. All the Features …

Investigation on Automation of Lathe Machine. While the manual lathe machines are economical, Manufacturing and assembly is done to convert convectional lathe machine into CNC Machine.

You can buy CNC Toolroom lathes that are set up the same as any manual lathe and they’re a wonder to use. One of the reasons I got into CNC was I had a good machinist friend who encouraged me to put all of my manual machining activity aside and focus on getting my CNC mill up and running.

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i’ll have to tune the lathes

7-2-2020 · Lathe CNC Upgrade Is Nothing To Shake A Turned I have one of those lathes and I’m into CNC (mill jog X and Z axes respectively and use your cnc lathe just as if it was manual

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

Note that I am using the lathe in “diameter mode”, as opposed to “radius mode”, as in normal manual operations. I am also working with X toward me, and X- on the further side of the spindle centerline, though backward, it was the only way I could get the code, the screen, and the cutting tool to agree on the same plan of action.

Conversion of the prototype Myford lathe. This page records the steps in the development of a prototype MC-KIT application, in this case a lathe. Similar principles would apply to the conversion of any machine tool, basically involving the replacement of manual handwheels and …

This Bolt-on X & Z Axis ball screw kit is designed and built by BDTOOLSUSA, not the manufacturer, to convert your Grizzly G0602 or G0752, 10 x 22 manual lathe to CNC using the mounts and ball screws supplied in this listing. All parts are custom made to assure proper fit and are designed to install into the original mounting holes.

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

CNC Lathe Machine 1340 Turning Center for Sale CNC Masters

CNC Lathe Design Details Wade’O Design

Spring pole lathes were in common use into the early 2. Exact drawing made with camera obscura of horizontal boring machine by Jan Verbruggen in Woolwich Royal Brass Foundry approx. Convert Manual Lathe Cnc’ title=’Convert Manual Lathe Cnc’ /> An important

28-5-2018 · Hi. I was wondering if there’s been any progress? I’m wanting to build a CNC lathe to go with the rest of my automated shop and I’m looking for direction and perhaps a bit of inspiration too. I keep debating if I should follow the path you are following with a “doner” lathe of some sort, or just start from scratch building the whole thing.

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

Combination Cnc Manual Lathe Conversion >>>CLICK HERE<<< I am converting a Big Dog 7×14 lathe to CNC, I know virtually nothing about CNC, If a manual lathe, you will also have to convert to Balls screws for axis drives. My old lathe ran using a USB SS combined with a CNC4PC break out board. Conversions The Tormach 15L Slant-PRO™

CNC Masters is pleased to introduce our own brand of CNC lathe technology. By combining what machinists look for in a manual lathe together with the perks of CNC, our 1440 CNC Lathe and CNC 1340 Lathe were made to address the needs of businesses, hobbyists, and …

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

CNC Lathe Machines offered by ARUN ENGINEERS & CONSULTANTS, We also supply kits to convert Manual operated Lathe Machines into CNC Lathe Machines. Any manual operated Lathe can be converted to to CNC Operated Lathe machines using our Lathe conerssion Kits.

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

Convert a Manual Mill into a CNC Machine Make

Lathe variable speed conversion – Turn Spain – Woodturning

Why Convert? If you’re thinking of converting your tired lathe or mill to CNC, I recommend you do so as it can be a fun and intensely rewarding project. Before you do, it’s probably a good idea to consider what you typically use it for and whether a CNC conversion will help you do it better or faster.

General Design: The CNC conversion of my Grizzly 10×22 G0752 (G0602) Lathe will be composed of two completely independent control systems.First, and simplest, I want to be able to perform CNC machining on the lathe using Mach4 software. Second, I want to retain all manual lathe functionality.

26-1-2008 · How to convert manual Lathe into CNC Lathe?

Turning and Lathe Basics Fundamental Manufacturing Processes Video Series Study Guide – 7 – chuck A device attached to the work spindle that holds the workpiece, usually gripping it with jaws or fingers.

Investigation on Automation of Lathe Machine. While the manual lathe machines are economical, Manufacturing and assembly is done to convert convectional lathe machine into CNC Machine.

Instead of buying a CNC machine, learn how to convert a manual mill into one. 18 Responses to CNC Mini Mill Conversion Kit (Hardware) Leave a Reply Cancel reply. I figured since I have a lathe and mill I would build my own,

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

Combination Cnc Manual Lathe Conversion >>>CLICK HERE<<< I am converting a Big Dog 7×14 lathe to CNC, I know virtually nothing about CNC, If a manual lathe, you will also have to convert to Balls screws for axis drives. My old lathe ran using a USB SS combined with a CNC4PC break out board. Conversions The Tormach 15L Slant-PRO™

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

19-11-2017 · This conversion is a bit unique as it uses dual controllers; one for CNC with Mach4 and another to drive all the original manual controls with an Arduino UNO. Visit my website www.wadeodesign.com

Variable Speed Lathe Conversion Tips DoItYourself.com

Building an Arduino Controlled Lathe Make

When considering converting a manual lathe to a CNC lathe you need to take into account what the typical use of the lathe is and determine if the conversion to a CNC lathe will improve your process. CNC (computer numerical controlled) lathe conversions are beneficial if moving into some type of production and if you really know what you are doing.

A short video showing the converted lathe cutting aluminum. Since being new at cnc lathe cutting, I set the roughing pass at 5ipm and the finished pass at 1ipm. The lathe does cut much faster but just playing it safe with the feed/speed for now. Backlash on both axis is very minimal, almost none, due to the high grade THK ground ball screws.

Combination Cnc Manual Lathe Conversion >>>CLICK HERE<<< I am converting a Big Dog 7×14 lathe to CNC, I know virtually nothing about CNC, If a manual lathe, you will also have to convert to Balls screws for axis drives. My old lathe ran using a USB SS combined with a CNC4PC break out board. Conversions The Tormach 15L Slant-PRO™

Why Convert? If you're thinking of converting your tired lathe or mill to CNC, I recommend you do so as it can be a fun and intensely rewarding project. Before you do, it's probably a good idea to consider what you typically use it for and whether a CNC conversion will help you do it better or faster.

Note that I am using the lathe in “diameter mode”, as opposed to “radius mode”, as in normal manual operations. I am also working with X toward me, and X- on the further side of the spindle centerline, though backward, it was the only way I could get the code, the screen, and the cutting tool to agree on the same plan of action.

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. All the Features …

24-7-2018 · After learning how to thread on a manual lathe properly, my first experience threading via cnc was really humbling. less than 90 seconds to face, turn and thread a tube with perfect accuracy. I will post some stills of the threads but they came out beautiful.

CNC Lathe 1340 Turning Center. This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

When converting a fixed lathe to a variable speed lathe take all necessary safety precautions. Since you will be working with electrical wiring, consult an electrician if needed. Refer to the original user manual to ensure that the proper equipment is being used in the installation of the new motor.

7-2-2020 · Lathe CNC Upgrade Is Nothing To Shake A Turned I have one of those lathes and I’m into CNC (mill jog X and Z axes respectively and use your cnc lathe just as if it was manual

and manual updates for free on our website at www.grizzly.com. alternatively, you can call our technical support for help. Before calling, please write down the Manufacture Date and Serial Number stamped into the machine id label (see below). this infor-mation helps us determine if updated documenta-tion is available for your machine.

CNC Masters is pleased to introduce our own brand of CNC lathe technology. By combining what machinists look for in a manual lathe together with the perks of CNC, our 1440 CNC Lathe and CNC 1340 Lathe were made to address the needs of businesses, hobbyists, and …

19-11-2017 · This conversion is a bit unique as it uses dual controllers; one for CNC with Mach4 and another to drive all the original manual controls with an Arduino UNO. Visit my website www.wadeodesign.com

Investigation on Automation of Lathe Machine. While the manual lathe machines are economical, Manufacturing and assembly is done to convert convectional lathe machine into CNC Machine.

Convert a Manual Mill into a CNC Machine in 2019 Cnc

9×20 Lathe CNC conversion The Hobby-Machinist

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

You can buy CNC Toolroom lathes that are set up the same as any manual lathe and they’re a wonder to use. One of the reasons I got into CNC was I had a good machinist friend who encouraged me to put all of my manual machining activity aside and focus on getting my CNC mill up and running.

7-2-2020 · Lathe CNC Upgrade Is Nothing To Shake A Turned I have one of those lathes and I’m into CNC (mill jog X and Z axes respectively and use your cnc lathe just as if it was manual

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

22-7-2018 · I have an HC Super Precision, but I’m not going to convert it, as it is too nice of a manual lathe. OT-CNC wrote: In my case I already had a solid base , z axis and spindle to work off but needed to add ball screws and a totally custom x axis.

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i’ll have to tune the lathes

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

Turning and Lathe Basics Fundamental Manufacturing Processes Video Series Study Guide – 7 – chuck A device attached to the work spindle that holds the workpiece, usually gripping it with jaws or fingers.

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

28-5-2018 · Hi. I was wondering if there’s been any progress? I’m wanting to build a CNC lathe to go with the rest of my automated shop and I’m looking for direction and perhaps a bit of inspiration too. I keep debating if I should follow the path you are following with a “doner” lathe of some sort, or just start from scratch building the whole thing.

Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion. Aug 20, 2019 – Instead of buying a CNC machine, learn how to convert a manual mill into one.

CNC Lathe Machine 1340 Turning Center for Sale CNC Masters

Building an Arduino Controlled Lathe Make

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

Combination Cnc Manual Lathe Conversion >>>CLICK HERE<<< I am converting a Big Dog 7×14 lathe to CNC, I know virtually nothing about CNC, If a manual lathe, you will also have to convert to Balls screws for axis drives. My old lathe ran using a USB SS combined with a CNC4PC break out board. Conversions The Tormach 15L Slant-PRO™

Let’s learn to Convert Manual Guide programs into normal vanilla CNC Code. Manual Guide i is very popular now on Fanuc Controls. I’ve got to be honest I’m not a great fan. There are parts of it that are very useful. But anyway knowing me Ill probably change my mind. I do work in some companies that just use manual guide and nothing

Converting a Logan 11" x 32" Lathe over to full CNC, Part 1: As handy as a manual turret lathe is, I decided it was time to add some true CNC to my shop. Not wanting to finance a new K machine, I instead elected to convert my turret lathe over to computer control, using fairly standard open-loop steppers.

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

After picking up a vintage Delta Homecraft wood lathe from a garage sale, Chris decided to convert to CNC using an Arduino: I found an old lathe at a garage sale and decided to turn it into a router lathe for cutting spirals, flutes and threads.

17-10-2018 · A chart representing the sequence of retrofitting operations to convert the lathe into a CNC spinning system is shown in Fig. 2. This requires the addition of actuators, sensors, CNC controller, CNC software, and some mechanical elements.

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

19-10-2012 · 9×20 Lathe CNC conversion. Thread starter jumps4; Start i didnt want to alter any of the original parts too much so i can return to lathe to manual if i just 2 axis. the speed it is moving in the vid doesnt mean anything the motor driving it is from my mill just plugged into the lathe to test the movement. i'll have to tune the lathes

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5" diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

Lathe conversion to CNC -3 Ball Screws Backlash is annoying on a manual lathe, but it is very important on the cross slide of a CNC lathe. and a thread pitch of no more than 5mm. The cross slide nut needed to be a THK BNT pattern in order to fit into the cross slide with a …

Instead of buying a CNC machine, learn how to convert a manual mill into one. 18 Responses to CNC Mini Mill Conversion Kit (Hardware) Leave a Reply Cancel reply. I figured since I have a lathe and mill I would build my own,

CNC Lathes were made to change the current manual production lathes also known as carbide tooling. These lathes considered "CNC Lathes" are controlled by a machine tool paths and programmed by popular langagues called CAD.CNC Lathe Manufacturers include Haas, Mazak, DMG Mori, Doosan and Johnfords with models in various sizes, types and functionalities but all help in automating and …

Combination Cnc Manual Lathe Conversion WordPress.com

9×20 Lathe CNC conversion The Hobby-Machinist

Posted in r/CNC by u/davemo37 • 4 points and 17 comments

Lathe machine introduction. The Lathe was invented by Jacques de Vaucanson around 1751.. The Lathe Machine is an ancient tool. At the very early stage this machine was developed around 1300 BC at that time there was not developed so many parts expect headstock and Tailstock.

28-5-2018 · Hi. I was wondering if there’s been any progress? I’m wanting to build a CNC lathe to go with the rest of my automated shop and I’m looking for direction and perhaps a bit of inspiration too. I keep debating if I should follow the path you are following with a “doner” lathe of some sort, or just start from scratch building the whole thing.

A short video showing the converted lathe cutting aluminum. Since being new at cnc lathe cutting, I set the roughing pass at 5ipm and the finished pass at 1ipm. The lathe does cut much faster but just playing it safe with the feed/speed for now. Backlash on both axis is very minimal, almost none, due to the high grade THK ground ball screws.

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

I found the four speed conversion a limitation and wanted a variable speed lathe. I don’t turn very large items and I have a considerable investment in accessories for this lathe (chucks, drives, tool rests etc) and so felt that it was better to upgrade to variable speed rather than replace it. This is a description of how I performed the

22-7-2018 · I have an HC Super Precision, but I’m not going to convert it, as it is too nice of a manual lathe. OT-CNC wrote: In my case I already had a solid base , z axis and spindle to work off but needed to add ball screws and a totally custom x axis.

20-9-2016 · Hi all, I have a Sherline lathe that I would like to convert from manual control to CNC. I have no real hands-on experience with CNC and am hoping that some people here could help me sort out a general plan of what to get in order to implement EMC2 software.

17-10-2018 · A chart representing the sequence of retrofitting operations to convert the lathe into a CNC spinning system is shown in Fig. 2. This requires the addition of actuators, sensors, CNC controller, CNC software, and some mechanical elements.

CNC Lathe 1340 Turning Center. This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

Spring pole lathes were in common use into the early 2. Exact drawing made with camera obscura of horizontal boring machine by Jan Verbruggen in Woolwich Royal Brass Foundry approx. Convert Manual Lathe Cnc’ title=’Convert Manual Lathe Cnc’ /> An important

New Post, “How to convert manual Lathe into CNC Lathe?” – http://bit.ly/99NOVK

Converting a CNC Mill into a CNC Lathe. Occasionally I have really wished for a CNC lathe to tackle the occasional job that comes along that is too difficult to tackle on a manual lathe. I have seen instances of a milling machine being used as a lathe by holding the work piece in the vertical spindle and clamping the turning tool to the machine table.

25-7-2013 · Convert Manual lathe to cnc Hey everyone I’m going to ask for help on retrofitting a pair of manual lathe’s to cnc anybody with experience please give me any advice. One is a hardinge dove tail we use to slice blanks of of a tube. we use 2 cutting tools to for this operation.

Converting a Logan 11″ x 32″ Lathe over to full CNC, Part 1: As handy as a manual turret lathe is, I decided it was time to add some true CNC to my shop. Not wanting to finance a new K machine, I instead elected to convert my turret lathe over to computer control, using fairly standard open-loop steppers.

Turning and Lathe Basics Manufacturing

(PDF) Investigation on Automation of Lathe Machine

19-11-2017 · Home › Forums › “Zebra” Adidas Yeezy Boost 350 V2 Restock Will Reportedly Be More Available This Time › Converting a manual lathe to cnc @874@ Tagged: a, cnc, Converting, lathe, manual, to 0 replies, 1 voice Last updated by tkngoedidj 9 months, 2 weeks ago Viewing 1 post (of 1 total) Author Posts January 7, […]

A short video showing the converted lathe cutting aluminum. Since being new at cnc lathe cutting, I set the roughing pass at 5ipm and the finished pass at 1ipm. The lathe does cut much faster but just playing it safe with the feed/speed for now. Backlash on both axis is very minimal, almost none, due to the high grade THK ground ball screws.

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. All the Features …

Note that I am using the lathe in “diameter mode”, as opposed to “radius mode”, as in normal manual operations. I am also working with X toward me, and X- on the further side of the spindle centerline, though backward, it was the only way I could get the code, the screen, and the cutting tool to agree on the same plan of action.

How To Level A Manual Lathe Into Cnc Lathe Read/Download it was very cost-effective to convert the Taig Micro Lathe to CNC by installing different The motor has a 1.5″ diameter lip that fits into & centers on the NEMA 23 Direction of the micro-switch level points to which mini-stereo input jack is CNC rotary table were mounted onto the

Instead of buying a CNC machine, learn how to convert a manual mill into one. This project will only cover the physical hardware conversion.

Posted in r/CNC by u/davemo37 • 4 points and 17 comments

CNC Lathe 1340 Turning Center. This is an elite CNC Lathe machine that seamlessly converts back to all original manual modes for added flexibility. Delivering high-level performance with a smaller footprint, the CNC 1340 Turning Center provides great value.

General Design: The CNC conversion of my Grizzly 10×22 G0752 (G0602) Lathe will be composed of two completely independent control systems.First, and simplest, I want to be able to perform CNC machining on the lathe using Mach4 software. Second, I want to retain all manual lathe functionality.

22-7-2018 · I have an HC Super Precision, but I’m not going to convert it, as it is too nice of a manual lathe. OT-CNC wrote: In my case I already had a solid base , z axis and spindle to work off but needed to add ball screws and a totally custom x axis.

This procedure assumes that you have went through the steps before spindle centerline in the ST, DS – Field Service Lathe Level and Alignment Checklist.If not, do this now to ensure that you do not induce errors from other components that could be out of alignment.

20-9-2016 · Hi all, I have a Sherline lathe that I would like to convert from manual control to CNC. I have no real hands-on experience with CNC and am hoping that some people here could help me sort out a general plan of what to get in order to implement EMC2 software.