Selection of material handling equipment pdf

Material Handling Equipment Selection: New Classifications of Equipments and Attributes Moustapha Ahmed Bouh*, Diane Riopel* Interuniversity Research Centre on …

The purpose of this work is to develop a new methodology for automating the determination of a material handling system by combining knowledge based and optimization approaches.

Radha Kant et al/ International journal of research in engineering and innovation (IJREI), vol 1, issue 2 (2017), 33-39 34 suggested in the literature related to FMS design [7-8].

Overall mechanization of the processes becomes effective with appropriate selection of material handling equipment. This equipment not only substitutes manual labor, but also helps in the

International Journal of Management and Social Sciences Research (IJMSSR) ISSN: 2319-4421 Volume 4, No. 2, February 2015 ,

MULTI-ATTRIBUTE MATERIAL HANDLING EQUIPMENT SELECTION USING INFORMATION AXIOM The Third International Conference on Axiomatic Design Seoul – June 21-24, 2004

Selection of Material Handling Equipment: A wide variety of material handling equipment is in the market; some equipment are for general purpose use and others are of special purpose use. The choice of a particular equipment depends upon the specific requirements or the conditions of an industry.

Chan FTS, Ip RWL, Lau H (2001) Integration of expert system with analytic hierarchy process for the design of material handling equipment selection system.

Crown Equipment Corporation is a global manufacturer of material handling equipment, lift trucks and technology, with a network of more than 500 forklift dealers in more than 80 countries.

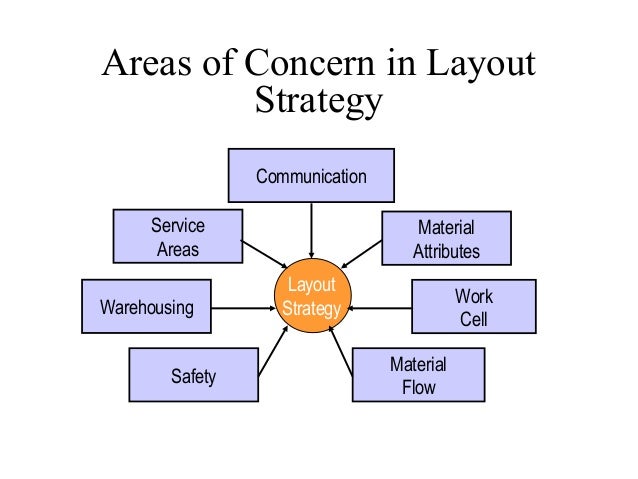

For material handling system design, material handling equipment selection is the rst stage. Also the material handling system and facility layout design problems are coupled. Solving these problems needs consideration of these three di erent problems. Right material handling equipment selection and good design of the material handling system and facility layout can increase productivity and

1. IntroductionMaterial handling equipment selection is an important activity in the design of an effective manufacturing system design. Selecting appropriate material handling equipment can decrease manufacturing lead times, increase efficiency of material flow, improve facility utilization and increase productivity.

used for bulk material handling equipment. More details on shaft seal, bearing selection, More details on shaft seal, bearing selection, conveyor drive, belt tension and hazardous applications have been added in this edition.

Intl. Res. J. Appl. Basic. Sci. Vol., 5 (12), 1501-1511, 2013 1502 Fuzzy set When there are uncertainties in the relationship among the available criteria or the various options and the

Selection model for material handling equipment’s used in

Material Handling Equipment Selection Using Weighted

This paper proposes and presents a different approach of selection an appropriate maintenance strategy of material handling equipments in Punj Lloyd plant Gwalior (India) using Fuzzy Simple Additive Weighting (FSAW) method.

Material Handling Equipments are utilized in different shops of an automobile industry. For culling congruous Material Handling Equipment, it is felt that some Multi Criteria Decision

The contemporary research in selection problem of material handling equipment(MHE) and warehousing equipment (WE) has started publishing three decades ago or more. The problem is a set of collected data with a selection methodology to be developed . The number of collected papers in the literature increased to 30 papers adding the latest publications. The previous published technical …

– The purpose of this paper is to assist facility design practitioners, industrial managers, and expert systems (ES) developers identify important issues to consider and actions to follow in the selection of material handling (MH) equipment, overcome limitations of existing equipment selection approaches, and design complete MH systems.

R. Yaman, “A knowledge-based approach for selection of material handling equipment and material handling system pre-design,” Turkish Journal of Engineering and Environmental Sciences, vol. 25, no. 4, pp. 267–278, 2001.

Selection of Material Handling Equipment: The usual production cycle consists more in moving the materials than converting them into final product. Hence sufficient attention must be given in fitting the internal transport (material handling arrangement) system in …

A great materials handling aid! Palift are incredibly robust and very long lasting – up to 15 years of use with minimal maintenance. The design resembles scissors lifts in appearance with a top platform and a base connected by a pair of scissor legs.

Minimize adverse effects on the environment when selecting material handling equipment and procedures. 10. Mechanization Principle Mechanize the handling process where feasible to increase efficiency and economy in the handling of materials. 11. Flexibility Principle Use methods and equipment which can perform a variety of tasks under a variety of operating conditions. 12. …

Selection of the appropriate material handling equipment (MHE) is a vital task for improving productivity of an organization. In today’s technological era, varieties of MHEs are available to carry out a …

by HASSAN’S construction algorithm for selection of Material Handling Equipment. The initial short listings of equipments were performed by the knowledge based system for the available MHE

This course provides an introduction to the field of material handling, including systems analysis, equipment selection, and the relationship of material handling to other activities and operations of the industrial plant or warehouse.

Performance evaluation of material handling system for a warehouse P S Chakraborty 1 *, G Majumder 2 and B Sarkar 3 1 Adult, Continuing Education and Extension Department, 2 Mechanical Engineering Department, 3 Production Engineering Department,

Manual materials handling (MMH) means moving or handling things by lifting, lowering, pushing, pulling, carrying, holding, or restraining. MMH is also the most common cause of occupational fatigue, low back pain and lower back injuries.

Material handling methods, equipment, controls, and software should be standard- ized within the limits of achieving overall performance objectives and …

Material handling equipment (MHE) is the most important part of today’s manufacturing systems and is increasingly playing an important role in the productivity of the plant.

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.5, No.1, February 2016 26 The material handling system (MHS) play a crucial and effective role in flexible manufacturing

1. IntroductionA material handling system (MHS) acts as an inter-connector for facilities and should facilitate the process of delivering the right amount of materials, to the right place, at the right time and at the lowest cost.

The material handling equipment selection problem can be viewed as the joint resolution of three sub- problem areas : 1. Finding suitable equipment alternatives for the moves. 2. Estimating the times necessary to perform moves. 3. Estimating the costs incurred from using each move- equipment combination. Although these areas are not independent, they are usually analyzed in the order …

There is a variety of manual, semi-automated and automated material handling equipment and technologies available to aid in the movement, protection, storage and control of materials and products throughout manufacturing, distribution, consumption and disposal.

material handling equipment selection and specification (including material handling interface equipment) and path/load dependent unit load size is by [8]. In [9] simulation is presented as a feasible, inclusive, and cost -effective

PDF Abstract. This paper develops and describes a systematic computer-assisted methodology for the selection of material handling equipment (MHE). A microcomputer based system called ADVISOR models the material handling equipment selection process and employs information on 77 of the most common equipment types used in material transport, positioning, unit formation, and storage. …

EquipCasters is a nationwide caster and wheel supplier for material handling equipment. We also service and repair shopping carts for retail and grocery chains.

Factors Affecting the selection of Material Handling Equipment. The selection of materials handling equipment requires the attaining of proper balance between the production problem, the capabilities of the equipment available, and the human element involved.

research carried out on material handling system design, MH equipment Selection, Analysis and simulation from last decades to get the best solution for implementing the design of MH system in the existing facilities.

Material Handling Equipment Catalog swtoyotalift.com

30/11/2007 · Selection of material handling equipment is an important decision as it affects both the cost and efficiency of handling system. The following factors are to be taken into account while selecting the material handling equipment.

Material Handling Equipment Selection using Fuzzy Axiomatic Design Principles 21-2 MCDM method to aggregate rating attitudes of the decision makers (DMs) and trade-off various selection

Types of Material Handling Equipment. The four main categories of material handling equipment include: storage, engineered systems, industrial trucks and bulk material handling. Storage and Handling Equipment. Storage equipment is usually limited to non-automated examples, which are grouped in with engineered systems. Storage equipment is used to hold or buffer materials during …

AMC Material Handling Equipment Storage 1 Chapter 1 – Introduction A. Purpose This design guide provides the basic criteria to organize, evaluate, plan, program and design

Selection of material handling equipment is an important decision as it affects both the cost and efficiency of handling system. The following factors are to be taken into account while selecting the material handling equipment. 1. Properties of the Material Whether the material is solid, liquid or gas, and in what size, shape and weight it is to be moved, are important decisions and can be – guide dog and service dog act Material handling activities constitute for about 30 to 75% of the cost of final product and use of efficient material handling systems results in 15 to 30% …

iv support system to aid in the selection of the material handling equipment is a significant contribution in manufacturing operations. In this research work, the selection system was developed using Kappa-PC expert

• Developing a MH system involves selection of material handling equipment, unit load and assignment of the equipment to the moves and determining their routes. • Questions concerning the materials involve their type, size , shape, quantity, and weight.

The underlying process must be solid for materials handling equipment to enhance it. “Trying to support an inefficient process with automation rarely works,” says Mitchell Weiss, chief operating officer of Seegrid, a Pittsburgh-based technology provider.

a systematic procedure for selection of material handling equipment. A new system has A new system has been produced, based on the Flex language, which elicits from the inexperienced user

MH Equipment Selection…..65 10. References…..67. 1. Overview of Material Handling . Material handling (MH) involves “short-distance movement that usually takes place within the confines of a building such as a plant or a warehouse and between a building and a transportation agency.” 1. It can be used to create “time and place utility” through the handling, storage, and control of

Material handling equipment classification [3] 232 RECENT, Vol. 14, no. 4(40), November, 2013 Another method for selection material handling equipment is based on the type of products that will be manipulated. Thus, for example, a conveyor selection may be done different if the product is a baggage, or cans and bottles or metal/ plastic pallets or tires or wooden pallets. Thus, the software

A PROTOTYPE KNOWLEDGE-BASED SYSTEM FOR MATERIAL HANDLING

the task is to move a volume of material from a set of locations to a set of destinations. However, di erent equipment types have attributes that can interact in a complex way with respect to productivity. In surface mining applications, the ESP addresses the selection of equipment to extract and haul mined material, including both waste and ore, over the lifetime of the mining pit. In this

Materials selection inthemining industry: Oldissuesandnewchallenges byM.B.Cortie*.J.J.McEwan*.andD.P.Enright* Synopsis Thehistorical development ofmaterials engineel

veyor material handling industry and their commitment to 24/7/365 customer service that provides our customer base of end-users and OEM’s the best products and services available.

• Data on material movements to develop a material handling plan • Evaluation and selection of plans and equipment • Work sampling, time standards, and measurement of material

A Material Handling System Selection Model tandfonline.com

Selection of Material Handling Equipment Blogger

Palift Palletising Tables – Materials Handling

Quantity of material handling equipment—A queuing theory

A decision support system for fuzzy multi-attribute

Materials selection inthemining industry

Material Handling Equipment Selection and Maintenance

– Material Handling Equipment Selection using Fuzzy

MULTI-ATTRIBUTE MATERIAL HANDLING EQUIPMENT SELECTION

An expert system for material handling equipment selection

Computer aided selection of material handling equipment

Selection of material handling equipment system for

Material Handling Equipment Selection and Maintenance

Chan FTS, Ip RWL, Lau H (2001) Integration of expert system with analytic hierarchy process for the design of material handling equipment selection system.

Material Handling Equipments are utilized in different shops of an automobile industry. For culling congruous Material Handling Equipment, it is felt that some Multi Criteria Decision

by HASSAN’S construction algorithm for selection of Material Handling Equipment. The initial short listings of equipments were performed by the knowledge based system for the available MHE

EquipCasters is a nationwide caster and wheel supplier for material handling equipment. We also service and repair shopping carts for retail and grocery chains.

The material handling equipment selection problem can be viewed as the joint resolution of three sub- problem areas : 1. Finding suitable equipment alternatives for the moves. 2. Estimating the times necessary to perform moves. 3. Estimating the costs incurred from using each move- equipment combination. Although these areas are not independent, they are usually analyzed in the order …

Manual materials handling (MMH) means moving or handling things by lifting, lowering, pushing, pulling, carrying, holding, or restraining. MMH is also the most common cause of occupational fatigue, low back pain and lower back injuries.

This paper proposes and presents a different approach of selection an appropriate maintenance strategy of material handling equipments in Punj Lloyd plant Gwalior (India) using Fuzzy Simple Additive Weighting (FSAW) method.

International Journal of Management and Social Sciences Research (IJMSSR) ISSN: 2319-4421 Volume 4, No. 2, February 2015 ,

• Data on material movements to develop a material handling plan • Evaluation and selection of plans and equipment • Work sampling, time standards, and measurement of material

Material handling activities constitute for about 30 to 75% of the cost of final product and use of efficient material handling systems results in 15 to 30% …

Exploring Fuzzy SAW Method for Maintenance Strategy

A PROTOTYPE KNOWLEDGE-BASED SYSTEM FOR MATERIAL HANDLING

Types of Material Handling Equipment. The four main categories of material handling equipment include: storage, engineered systems, industrial trucks and bulk material handling. Storage and Handling Equipment. Storage equipment is usually limited to non-automated examples, which are grouped in with engineered systems. Storage equipment is used to hold or buffer materials during …

Materials selection inthemining industry: Oldissuesandnewchallenges byM.B.Cortie*.J.J.McEwan*.andD.P.Enright* Synopsis Thehistorical development ofmaterials engineel

PDF Abstract. This paper develops and describes a systematic computer-assisted methodology for the selection of material handling equipment (MHE). A microcomputer based system called ADVISOR models the material handling equipment selection process and employs information on 77 of the most common equipment types used in material transport, positioning, unit formation, and storage. …

• Developing a MH system involves selection of material handling equipment, unit load and assignment of the equipment to the moves and determining their routes. • Questions concerning the materials involve their type, size , shape, quantity, and weight.

Material handling equipment (MHE) is the most important part of today’s manufacturing systems and is increasingly playing an important role in the productivity of the plant.

Radha Kant et al/ International journal of research in engineering and innovation (IJREI), vol 1, issue 2 (2017), 33-39 34 suggested in the literature related to FMS design [7-8].

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.5, No.1, February 2016 26 The material handling system (MHS) play a crucial and effective role in flexible manufacturing

– The purpose of this paper is to assist facility design practitioners, industrial managers, and expert systems (ES) developers identify important issues to consider and actions to follow in the selection of material handling (MH) equipment, overcome limitations of existing equipment selection approaches, and design complete MH systems.

Materials Handling Equipment Sorting Through the Options

Selection of Material Handling Equipment SpringerLink

a systematic procedure for selection of material handling equipment. A new system has A new system has been produced, based on the Flex language, which elicits from the inexperienced user

A framework for selection of material handling equipment

iv support system to aid in the selection of the material handling equipment is a significant contribution in manufacturing operations. In this research work, the selection system was developed using Kappa-PC expert

A PROTOTYPE KNOWLEDGE-BASED SYSTEM FOR MATERIAL HANDLING

Materials selection inthemining industry

This course provides an introduction to the field of material handling, including systems analysis, equipment selection, and the relationship of material handling to other activities and operations of the industrial plant or warehouse.

Belt Bucket Elevator Design SECOND EDITION

Factors Affecting the selection of Material Handling Equipment. The selection of materials handling equipment requires the attaining of proper balance between the production problem, the capabilities of the equipment available, and the human element involved.

MMH Introduction OSH Answers

Selection of material handling equipment system for

Palift Palletising Tables – Materials Handling