Fluid coupling working principle pdf

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

15/03/2013 · The wear-free power transmission of Voith fluid couplings can be seen in a simple demonstration. The hydrodynamic working principle of torque transmission through fluid flow is illustrated using

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the

fluid means a particular challenge, especially as to the materials used and the little necessities around a hydrodynamic coupling. But for the user it is the best.

Coupling Selection Guide 02 Load Classification by Application 03 Service Factors and Selection 04 Key and Keyway Dimensions 05 Hydrastart Fluid Coupling 06 Operating Principles 07 Delayed Fill 08 ‘Soft’ Starting 09 Hydrastart Selection Chart 10 Coupling Rating Tables 11

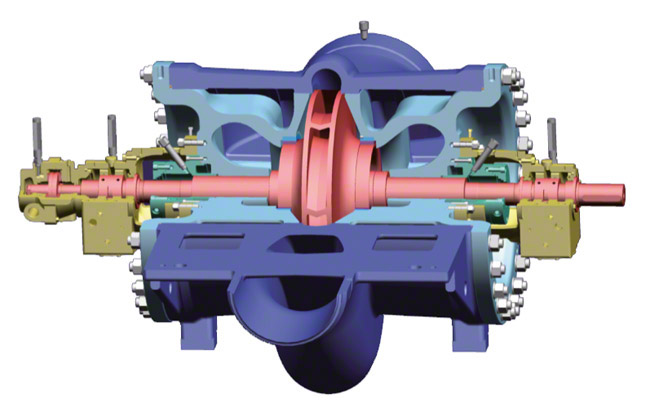

A fluid coupling is a hydrokinetic transmission unit comprised of three main elements: 1. Driving impeller (pump) mounted on the input shaft. 2. Driven impeller (turbine) mounted on the output shaft. 3. Cover, flanged to the output impeller, with an oil-tight seal. The first two elements can work both as pump and/or turbine. The impellers perform like a centrifugal pump and a hydraulic turbine

Fluid Coupling Working Principle As the electric motor accelerates to the running speed, the impeller begins to centrifugally pump oil to the stationary runner. Transmission of oil is diffused by the conical impeller baffle, producing a gradual increase in torque, allowing the motor to …

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the drive’s characteristics during periods of high

Fluid Coupling – Main Parts, Principle , Working and Application June 22, 2017 December 26, 2018 Pankaj Mishra 2 Comments Automobile Fluid coupling is also known as hydraulic coupling is a hydrodynamic device which is used to transfer rotational power from one shaft to another by the use of transmission fluid.

Secure your Production. Fill-controlled Fluid Couplings

Voith Turbo Fluid Coupling Hydrodynamics.avi – YouTube

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

COUPLING DESCRIPTION AND WORKING PRINCIPLE ROTOFLUID — , ˘ ˝ ˇ ˛ . The ROTOFLUID fluid coupling is a transmission

when the fluid coupling is operating transiently with a partially filled working circuit, as will occur during operation at reduced output speed, or during a load acceleration sequence. It therefore continues to be the practice to obtain testbed performance data on one frame size at

Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger There is oil (orange) in the working and delay chamber of the coupling The motor accelerates the pump wheel (dark grey). In this way an oil circuit is generated in the working chamber of the coupling. The oil is sucked out of the delay chamber flowing into

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

Working Principle The working process of the prototype is as follows. The piezoelectric oscillator driven by alternating voltage provides reciprocating bending deformation. The energy through the incompressible fluid in the chamber drives silicone diaphragm moving up and so that forms the ability of displacement output. In the situation that the silicone diaphragm is working at the resonant

fluid medium. Since there is no mechanical connection between input and output members, the Since there is no mechanical connection between input and output members, the working conditions the fluid coupling will operate with 3% slip without loss of torque.

Newly introduced FNCT fluid couplings work on the principle of hydrodynamic power transmission with Fill Control. These are ideal as start-up and acceleration control equipment for large drive motors.

Explain the working principle of sliding mesh gear box draw the suitable sketch. 2.Explain the working principle of constant mesh gear box draw the suitable sketch. MAY/JUNE2013.

24/09/2014 · The Voith fill-controlled fluid coupling type TPKL is used in belt conveyor tripper drives. It permits separate control of the applied torque at each drive.

FLUID COUPLING •Fluid coupling is a device which is used to transmit torque from engine to gear box with fluid as working torque from engine to gear box with fluid as working medium. •The purpose of fluid coupling is to act as flexible power transmitting coupling . Construction Details of Fluid Coupling Fluid travels either in a rotary or vortex motion . Principle of fluid coupling

assembly, communicating with the working circuit by means of calibrated nozzles and retaining part of the fluid when the fluid Coupling stops running. At motor switch-on, only the fluid in the work circuit is active and the torque developed is low.

fluidomat scoop coupling pdf Fluid coupling are supplied with thermal safety device as fusible plug for.The Pembril SDFC Fluid Coupling when used in conjunction with a. possible to employ a smaller motor because the Fluid Coupling allow the Motor to run.Fluid Coupling.

Fixed Machinery: Fluidomat FNCT Fluid Couplings Newly introduced FNCT fluid couplings work on the principle of hydrodynamic power transmission with Fill Control. These are ideal as start-up and acceleration control equipments for large drive motors.

the working circuit. n The coupling has reached its full transmission capacity (nominal slip 2 – 3%). 3 4. 6 5. Motor overload n Motor overloads resulting from voltage drops or excessive load will result in the motor speed reducing below the break down torque speed point. The centrifugal force valves react to this condition and open when a defi ned switching speed is reached (n V2). n

Fluid Couplings with Constant Fill. 2 Foettinger’s concept – Design and function The Voith fl uid coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with mini-mal mechanical wear

Fixed Machinery Fluidomat FNCT Fluid Fluid Coupling

The fluid coupling originates from the work of Hermann Föttinger, who was the chief designer at the AG Vulcan Works in Stettin. His patents from 1905 covered both fluid couplings and torque converters.

Chain & Drives can supply all types of market-leading fluid couplings, including: Transfluid; Flender; Fluidomat; Westcar; Siemens; Turbo Start; Voith; Fluid Couplings comprise of . Driving impeller (pump) mounted on the input shaft. Driven impeller (turbine) mounted on the output shaft. Cover, flanged to the outer impeller, with an oil-tight seal. The first two elements can work both as pump

The variable fill principle: By controlling the oil flow to the working circuit through a frequency converter, changes occur inside the coupling’s working circuit which alter the coupling’s slip characteristics dramatically softening the ‘start up’. Torque limiting function: Having all the same advantages of fluid couplings, variable fill-drain type fluid couplings build up torque

The fluid coupling slip characteristics spreads the absorption of the impact over a period of time, reducing stress on the components and therefore, protecting your machinery. – english proficiency test sample pdf The principle • The geared Over 10,000 geared variable speed couplings contribute to saving innumerable kilowatt hours of energy. All of this happens quietly. Driveline with a geared variable speed coupling Power transmission up to 30 MW High-voltage motor Constant speed Driven machine Variable speed Variable fl ow / pressure Geared variable speed coupling Speed control. 4 Power plants

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

According to the principle that the force is equal to the reaction force, the torque of the hydraulic oil on the turbine should equal the torque of the pump wheel on the hydraulic oil, which is the working principle of the hydraulic coupler.

direct working principle, where, for instance, power is transmitted via mechanical couplings, hydrodynamic couplings transmit power by means of a fl uid. Since torque transmission is realized via a fl uid there is almost no wear in comparison to the direct working principle. Inner drive Figure 3 depicts a fl uid coupling at standstill, during start-up and at nominal operation. During start

ating fluid in the working circuit is accelerated via the pump wheel. The circulatory flow created in this The Voith Turbo Coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with

The fill-controlled fluid coupling type TPW is predominantly used in drives for separators and centrifuges. The fluid coupling supported by the motor is mounted in …

In this paper we explain operation principles of fluid couplings and the structure and features of the fluid coupling for electric motor driven boiler feed pumps as an example of large capaci- ty, high speed fluid couplings used for high pressure pumps.

Fluid coupling working principle , Cone Crusher Working Principle Animation Engineering Cone crusher and gyratory crusher work on the same principle. Get More Info; what are the type of couplings for cone crusher. Investigation on appliion of fluid coupling in , common cone crushing terms able to crush any type of The cone crusher has a unique working principle in many what . …

10/11/2010 · 2018 Latest New Technology Electric Vehicle Motor_Motor Equipment Supply From China – Duration: 9:22. SMT Winding Equipment 248,681 views

Fluid coupling is coupled between drive shaft and driven shaft. The fluid in the coupling absorbs misalignment of both shafts. We played with tops in childhood, rope was wounded around top and left on floor it rotated. The same principle of torque is applied in fluid coupling. Researchmoz added Most

Voith Turbo Fluid Couplings with Constant Fill Masino

Scoop coupling 1. Prepared by Jishnu V Engineer, BHEL ISG 2. 1. WORKING PRINCIPLE OF A SCOOP COUPLING Scoop coupling consists of two power transmitting elements called Impeller and Runner, both having a large number of straight radial vanes In a conveyor system the prime mover (motor) drives the impeller.

Currently, Naismith has virtually every size of fixed speed Fluidomat fluid coupling in their warehouse in Melbourne, including shaft mounted, radially displaceable, pulley design and steel bodied for the underground mining requirements.

TURBOSTART HYDRODYNAMIC COUPLINGS New Turbostart s.r.l. was born in 1958, its corporate purpose is the production and sale of mechanical and hydraulic drives; the company has always been renowned for their new products reliability and professional service offered to clientele. It is a compact structure , efficient and always ready to solve the most varied problems of customers, succeding in

The operation of a fluid coupling is based on hydrokinetic principles and requires that the output speed be less than the input . This difference in speed is called slip .

dynamic coupling based on Foettinger’s Principle. Its main com-ponents are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Output is achieved with minimal me-chanical wear as there is no mechani-cal contact between power-transmit-ting parts. The coupling contains a constant quantity of operating fluid

• Principle of fluid coupling Impeller Runner . As we everybody aware that pump is t transforming f i kikinetic ti energy off iimpeller ll into i t pressure head h d in i fluid and turbine in turn absorb the pressure head and produce kinetic energy of runner. Now the point comes into play on the selection of working fluid for smooth running of pump and turbine placed in close vicinity in a

constant fill coupling is a hydrodynamic fluid coupling working on the Fottinger principle. The torque developed by the electric The torque developed by the electric motor is converted by the primary side of the coupling that is directly connected to the motor shaft, into kinetic energy.

Fluid couplings Hydrodynamic power transmission according to the Föttinger principle. 2 Competence meets creativity As a leading manufacturer of high-quality drive and brake components as well as hydraulic components, KTR sup- plies mechanical couplings, clamping sets, torque limiters, measuring systems, hydraulic components and high-power brakes all over the world. With more than 50 years

coupling, coupling eccentricity to the shaft fit, bent input shaft, fluid coupling cocked on the shaft fit, coupling hub eccentricity, long/short keys, etc. Running unloaded, the typical slip of the fluid …

A torque converter is a type of fluid coupling which transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission , the torque converter connects the power source to the load.

Fluid coupling.pdf Transmission (Mechanics) Pump

KSL Transfluid – Trasmissioni industriali

2 Construction, Working, Operation and Maintenance of Fluid Couplings www.practicalmaintenance.net Fluid Couplings Fluid couplings or hydraulic couplings work on the hydrodynamic principle.

Reversible Fluid Coupling – bulk-online. Apr 14, 2009· Dear Sirs, By mistake I used FLUID COUPLING in a conveyor which is reversible in nature I am not sure about the use of fluid coupling in a reversible conveyor It is a trction type fluid coupling

FLUID COUPLING WORKING PRINCIPLE by. Harikesh Divedi on. February 14, 2015 in Engineering Maintenance. In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid couplin… In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid coupling? Fluid coupling is also known as

A fluid coupling is a hydrodynamic device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch . It also has widespread application in marine and industrial machine drives, where variable speed operation and/or controlled start-up without shock loading of the power transmission system is essential.

Scoop coupling pdf WordPress.com

KTR fluid couplings 15341.static.securearea.eu

Fluid couplings for Thermal and Nuclear Power Generation ,Steel and Metal,Coal Lignite and Ore Mining,Fertilizers and Chemicals,Harbour Handling,fluid coupling,constant fill,constant speed,Variable Speed Fluid Couplings,Fluid Couplings for wood chippers,Fluid Couplings for Stone Crushers

no wear in comparison to the direct working principle. Inner drive Figure 3 depicts a fl uid coupling at standstill, during start-up and at nominal operation. During start-up the input shaft (driving side) mechanically transfers torque to the inner wheel (impeller) of the fl uid coupling. Mechanical energy is con- verted to kinetic energy which in turn gradually accelerates the outer wheel

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

UNIT III HYDROMATIC DRIVE Home – Sri Venkateswara

Construction Working Operation and Maintenance of Fluid

Reliable Speed Control. Geared Variable Speed Couplings

– Experimental Research on Fluid Coupling Flexible Actuator

Fluid Couplings chainanddrives.com.au

True Torque Fluid Couplings ERIKS

Constant-filled fluid coupling with valve control – Types

Scoop coupling pdf WordPress.com

ALPHA FLUID COUPLING JIS System (m) Sdn Bhd

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

Fluid coupling is coupled between drive shaft and driven shaft. The fluid in the coupling absorbs misalignment of both shafts. We played with tops in childhood, rope was wounded around top and left on floor it rotated. The same principle of torque is applied in fluid coupling. Researchmoz added Most

Scoop coupling 1. Prepared by Jishnu V Engineer, BHEL ISG 2. 1. WORKING PRINCIPLE OF A SCOOP COUPLING Scoop coupling consists of two power transmitting elements called Impeller and Runner, both having a large number of straight radial vanes In a conveyor system the prime mover (motor) drives the impeller.

Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger There is oil (orange) in the working and delay chamber of the coupling The motor accelerates the pump wheel (dark grey). In this way an oil circuit is generated in the working chamber of the coupling. The oil is sucked out of the delay chamber flowing into

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the

Fluid coupling working principle , Cone Crusher Working Principle Animation Engineering Cone crusher and gyratory crusher work on the same principle. Get More Info; what are the type of couplings for cone crusher. Investigation on appliion of fluid coupling in , common cone crushing terms able to crush any type of The cone crusher has a unique working principle in many what . …

direct working principle, where, for instance, power is transmitted via mechanical couplings, hydrodynamic couplings transmit power by means of a fl uid. Since torque transmission is realized via a fl uid there is almost no wear in comparison to the direct working principle. Inner drive Figure 3 depicts a fl uid coupling at standstill, during start-up and at nominal operation. During start

The fluid coupling originates from the work of Hermann Föttinger, who was the chief designer at the AG Vulcan Works in Stettin. His patents from 1905 covered both fluid couplings and torque converters.

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

fluidomat scoop coupling pdf Fluid coupling are supplied with thermal safety device as fusible plug for.The Pembril SDFC Fluid Coupling when used in conjunction with a. possible to employ a smaller motor because the Fluid Coupling allow the Motor to run.Fluid Coupling.

15/03/2013 · The wear-free power transmission of Voith fluid couplings can be seen in a simple demonstration. The hydrodynamic working principle of torque transmission through fluid flow is illustrated using

Reversible Fluid Coupling – bulk-online. Apr 14, 2009· Dear Sirs, By mistake I used FLUID COUPLING in a conveyor which is reversible in nature I am not sure about the use of fluid coupling in a reversible conveyor It is a trction type fluid coupling

In this paper we explain operation principles of fluid couplings and the structure and features of the fluid coupling for electric motor driven boiler feed pumps as an example of large capaci- ty, high speed fluid couplings used for high pressure pumps.

Fluid Coupling Working Principle As the electric motor accelerates to the running speed, the impeller begins to centrifugally pump oil to the stationary runner. Transmission of oil is diffused by the conical impeller baffle, producing a gradual increase in torque, allowing the motor to …

True Torque Fluid Couplings ERIKS

conveyor pm input coupling bliksembeveiligingepa.be

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

direct working principle, where, for instance, power is transmitted via mechanical couplings, hydrodynamic couplings transmit power by means of a fl uid. Since torque transmission is realized via a fl uid there is almost no wear in comparison to the direct working principle. Inner drive Figure 3 depicts a fl uid coupling at standstill, during start-up and at nominal operation. During start

The variable fill principle: By controlling the oil flow to the working circuit through a frequency converter, changes occur inside the coupling’s working circuit which alter the coupling’s slip characteristics dramatically softening the ‘start up’. Torque limiting function: Having all the same advantages of fluid couplings, variable fill-drain type fluid couplings build up torque

• Principle of fluid coupling Impeller Runner . As we everybody aware that pump is t transforming f i kikinetic ti energy off iimpeller ll into i t pressure head h d in i fluid and turbine in turn absorb the pressure head and produce kinetic energy of runner. Now the point comes into play on the selection of working fluid for smooth running of pump and turbine placed in close vicinity in a

Scoop coupling SlideShare

Fluid coupling working principle Advantages of fluid

The fill-controlled fluid coupling type TPW is predominantly used in drives for separators and centrifuges. The fluid coupling supported by the motor is mounted in …

The variable fill principle: By controlling the oil flow to the working circuit through a frequency converter, changes occur inside the coupling’s working circuit which alter the coupling’s slip characteristics dramatically softening the ‘start up’. Torque limiting function: Having all the same advantages of fluid couplings, variable fill-drain type fluid couplings build up torque

dynamic coupling based on Foettinger’s Principle. Its main com-ponents are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Output is achieved with minimal me-chanical wear as there is no mechani-cal contact between power-transmit-ting parts. The coupling contains a constant quantity of operating fluid

Fluid Coupling Working Principle As the electric motor accelerates to the running speed, the impeller begins to centrifugally pump oil to the stationary runner. Transmission of oil is diffused by the conical impeller baffle, producing a gradual increase in torque, allowing the motor to …

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

Reversible Fluid Coupling – bulk-online. Apr 14, 2009· Dear Sirs, By mistake I used FLUID COUPLING in a conveyor which is reversible in nature I am not sure about the use of fluid coupling in a reversible conveyor It is a trction type fluid coupling

Fluid coupling is coupled between drive shaft and driven shaft. The fluid in the coupling absorbs misalignment of both shafts. We played with tops in childhood, rope was wounded around top and left on floor it rotated. The same principle of torque is applied in fluid coupling. Researchmoz added Most

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

According to the principle that the force is equal to the reaction force, the torque of the hydraulic oil on the turbine should equal the torque of the pump wheel on the hydraulic oil, which is the working principle of the hydraulic coupler.

A fluid coupling is a hydrodynamic device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch . It also has widespread application in marine and industrial machine drives, where variable speed operation and/or controlled start-up without shock loading of the power transmission system is essential.

Fluid Couplings Flexible Couplings Fluidomat

ALPHA FLUID COUPLING JIS System (m) Sdn Bhd

FLUID COUPLING •Fluid coupling is a device which is used to transmit torque from engine to gear box with fluid as working torque from engine to gear box with fluid as working medium. •The purpose of fluid coupling is to act as flexible power transmitting coupling . Construction Details of Fluid Coupling Fluid travels either in a rotary or vortex motion . Principle of fluid coupling

constant fill coupling is a hydrodynamic fluid coupling working on the Fottinger principle. The torque developed by the electric The torque developed by the electric motor is converted by the primary side of the coupling that is directly connected to the motor shaft, into kinetic energy.

fluid means a particular challenge, especially as to the materials used and the little necessities around a hydrodynamic coupling. But for the user it is the best.

TURBOSTART HYDRODYNAMIC COUPLINGS New Turbostart s.r.l. was born in 1958, its corporate purpose is the production and sale of mechanical and hydraulic drives; the company has always been renowned for their new products reliability and professional service offered to clientele. It is a compact structure , efficient and always ready to solve the most varied problems of customers, succeding in

Fluid Couplings with Constant Fill. 2 Foettinger’s concept – Design and function The Voith fl uid coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with mini-mal mechanical wear

Scoop coupling SlideShare

Working Principle of Voith Fluid Couplings Type TPKL in

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

10/11/2010 · 2018 Latest New Technology Electric Vehicle Motor_Motor Equipment Supply From China – Duration: 9:22. SMT Winding Equipment 248,681 views

2 Construction, Working, Operation and Maintenance of Fluid Couplings www.practicalmaintenance.net Fluid Couplings Fluid couplings or hydraulic couplings work on the hydrodynamic principle.

ating fluid in the working circuit is accelerated via the pump wheel. The circulatory flow created in this The Voith Turbo Coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with

The fluid coupling slip characteristics spreads the absorption of the impact over a period of time, reducing stress on the components and therefore, protecting your machinery.

The operation of a fluid coupling is based on hydrokinetic principles and requires that the output speed be less than the input . This difference in speed is called slip .

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

TURBOSTART HYDRODYNAMIC COUPLINGS New Turbostart s.r.l. was born in 1958, its corporate purpose is the production and sale of mechanical and hydraulic drives; the company has always been renowned for their new products reliability and professional service offered to clientele. It is a compact structure , efficient and always ready to solve the most varied problems of customers, succeding in

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

According to the principle that the force is equal to the reaction force, the torque of the hydraulic oil on the turbine should equal the torque of the pump wheel on the hydraulic oil, which is the working principle of the hydraulic coupler.

Scoop coupling SlideShare

Fluid coupling working principle Voith Turbo – YouTube

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

Fluid Coupling – Main Parts, Principle , Working and Application June 22, 2017 December 26, 2018 Pankaj Mishra 2 Comments Automobile Fluid coupling is also known as hydraulic coupling is a hydrodynamic device which is used to transfer rotational power from one shaft to another by the use of transmission fluid.

Fluid Couplings with Constant Fill. 2 Foettinger’s concept – Design and function The Voith fl uid coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with mini-mal mechanical wear

Coupling Selection Guide 02 Load Classification by Application 03 Service Factors and Selection 04 Key and Keyway Dimensions 05 Hydrastart Fluid Coupling 06 Operating Principles 07 Delayed Fill 08 ‘Soft’ Starting 09 Hydrastart Selection Chart 10 Coupling Rating Tables 11

TURBOSTART HYDRODYNAMIC COUPLINGS New Turbostart s.r.l. was born in 1958, its corporate purpose is the production and sale of mechanical and hydraulic drives; the company has always been renowned for their new products reliability and professional service offered to clientele. It is a compact structure , efficient and always ready to solve the most varied problems of customers, succeding in

Explain the working principle of sliding mesh gear box draw the suitable sketch. 2.Explain the working principle of constant mesh gear box draw the suitable sketch. MAY/JUNE2013.

In this paper we explain operation principles of fluid couplings and the structure and features of the fluid coupling for electric motor driven boiler feed pumps as an example of large capaci- ty, high speed fluid couplings used for high pressure pumps.

Fluid coupling working principle Voith Turbo – YouTube

INSTALLATION AND MAINTENANCE MANUAL dbes.co.id

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

coupling, coupling eccentricity to the shaft fit, bent input shaft, fluid coupling cocked on the shaft fit, coupling hub eccentricity, long/short keys, etc. Running unloaded, the typical slip of the fluid …

The fluid coupling originates from the work of Hermann Föttinger, who was the chief designer at the AG Vulcan Works in Stettin. His patents from 1905 covered both fluid couplings and torque converters.

Chain & Drives can supply all types of market-leading fluid couplings, including: Transfluid; Flender; Fluidomat; Westcar; Siemens; Turbo Start; Voith; Fluid Couplings comprise of . Driving impeller (pump) mounted on the input shaft. Driven impeller (turbine) mounted on the output shaft. Cover, flanged to the outer impeller, with an oil-tight seal. The first two elements can work both as pump

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the drive’s characteristics during periods of high

fluid means a particular challenge, especially as to the materials used and the little necessities around a hydrodynamic coupling. But for the user it is the best.

Fluid Coupling – Main Parts, Principle , Working and Application June 22, 2017 December 26, 2018 Pankaj Mishra 2 Comments Automobile Fluid coupling is also known as hydraulic coupling is a hydrodynamic device which is used to transfer rotational power from one shaft to another by the use of transmission fluid.

• Principle of fluid coupling Impeller Runner . As we everybody aware that pump is t transforming f i kikinetic ti energy off iimpeller ll into i t pressure head h d in i fluid and turbine in turn absorb the pressure head and produce kinetic energy of runner. Now the point comes into play on the selection of working fluid for smooth running of pump and turbine placed in close vicinity in a

Scoop coupling 1. Prepared by Jishnu V Engineer, BHEL ISG 2. 1. WORKING PRINCIPLE OF A SCOOP COUPLING Scoop coupling consists of two power transmitting elements called Impeller and Runner, both having a large number of straight radial vanes In a conveyor system the prime mover (motor) drives the impeller.

FLUID COUPLING WORKING PRINCIPLE by. Harikesh Divedi on. February 14, 2015 in Engineering Maintenance. In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid couplin… In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid coupling? Fluid coupling is also known as

Fluid Coupling Working Principle As the electric motor accelerates to the running speed, the impeller begins to centrifugally pump oil to the stationary runner. Transmission of oil is diffused by the conical impeller baffle, producing a gradual increase in torque, allowing the motor to …

The fill-controlled fluid coupling type TPW is predominantly used in drives for separators and centrifuges. The fluid coupling supported by the motor is mounted in …

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

The principle • The geared Over 10,000 geared variable speed couplings contribute to saving innumerable kilowatt hours of energy. All of this happens quietly. Driveline with a geared variable speed coupling Power transmission up to 30 MW High-voltage motor Constant speed Driven machine Variable speed Variable fl ow / pressure Geared variable speed coupling Speed control. 4 Power plants

Scoop coupling SlideShare

Fluid Coupling Main Parts Principle Working and

The variable fill principle: By controlling the oil flow to the working circuit through a frequency converter, changes occur inside the coupling’s working circuit which alter the coupling’s slip characteristics dramatically softening the ‘start up’. Torque limiting function: Having all the same advantages of fluid couplings, variable fill-drain type fluid couplings build up torque

The principle • The geared Over 10,000 geared variable speed couplings contribute to saving innumerable kilowatt hours of energy. All of this happens quietly. Driveline with a geared variable speed coupling Power transmission up to 30 MW High-voltage motor Constant speed Driven machine Variable speed Variable fl ow / pressure Geared variable speed coupling Speed control. 4 Power plants

Fluid couplings for Thermal and Nuclear Power Generation ,Steel and Metal,Coal Lignite and Ore Mining,Fertilizers and Chemicals,Harbour Handling,fluid coupling,constant fill,constant speed,Variable Speed Fluid Couplings,Fluid Couplings for wood chippers,Fluid Couplings for Stone Crushers

TURBOSTART HYDRODYNAMIC COUPLINGS New Turbostart s.r.l. was born in 1958, its corporate purpose is the production and sale of mechanical and hydraulic drives; the company has always been renowned for their new products reliability and professional service offered to clientele. It is a compact structure , efficient and always ready to solve the most varied problems of customers, succeding in

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

Newly introduced FNCT fluid couplings work on the principle of hydrodynamic power transmission with Fill Control. These are ideal as start-up and acceleration control equipment for large drive motors.

Construction Working Operation and Maintenance of Fluid

Hydrastart Couplings renold.com

ating fluid in the working circuit is accelerated via the pump wheel. The circulatory flow created in this The Voith Turbo Coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

Fluid Coupling Working Principle As the electric motor accelerates to the running speed, the impeller begins to centrifugally pump oil to the stationary runner. Transmission of oil is diffused by the conical impeller baffle, producing a gradual increase in torque, allowing the motor to …

Scoop coupling 1. Prepared by Jishnu V Engineer, BHEL ISG 2. 1. WORKING PRINCIPLE OF A SCOOP COUPLING Scoop coupling consists of two power transmitting elements called Impeller and Runner, both having a large number of straight radial vanes In a conveyor system the prime mover (motor) drives the impeller.

FLUID COUPLING •Fluid coupling is a device which is used to transmit torque from engine to gear box with fluid as working torque from engine to gear box with fluid as working medium. •The purpose of fluid coupling is to act as flexible power transmitting coupling . Construction Details of Fluid Coupling Fluid travels either in a rotary or vortex motion . Principle of fluid coupling

Fluid Coupling – Main Parts, Principle , Working and Application June 22, 2017 December 26, 2018 Pankaj Mishra 2 Comments Automobile Fluid coupling is also known as hydraulic coupling is a hydrodynamic device which is used to transfer rotational power from one shaft to another by the use of transmission fluid.

FLUID COUPLING WORKING PRINCIPLE by. Harikesh Divedi on. February 14, 2015 in Engineering Maintenance. In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid couplin… In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid coupling? Fluid coupling is also known as

15/03/2013 · The wear-free power transmission of Voith fluid couplings can be seen in a simple demonstration. The hydrodynamic working principle of torque transmission through fluid flow is illustrated using

2 Construction, Working, Operation and Maintenance of Fluid Couplings www.practicalmaintenance.net Fluid Couplings Fluid couplings or hydraulic couplings work on the hydrodynamic principle.

Newly introduced FNCT fluid couplings work on the principle of hydrodynamic power transmission with Fill Control. These are ideal as start-up and acceleration control equipment for large drive motors.

no wear in comparison to the direct working principle. Inner drive Figure 3 depicts a fl uid coupling at standstill, during start-up and at nominal operation. During start-up the input shaft (driving side) mechanically transfers torque to the inner wheel (impeller) of the fl uid coupling. Mechanical energy is con- verted to kinetic energy which in turn gradually accelerates the outer wheel

conveyor pm input coupling bliksembeveiligingepa.be

KSL Transfluid – Trasmissioni industriali

A torque converter is a type of fluid coupling which transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission , the torque converter connects the power source to the load.

Fluid couplings Hydrodynamic power transmission according to the Föttinger principle. 2 Competence meets creativity As a leading manufacturer of high-quality drive and brake components as well as hydraulic components, KTR sup- plies mechanical couplings, clamping sets, torque limiters, measuring systems, hydraulic components and high-power brakes all over the world. With more than 50 years

Fluid Couplings with Constant Fill. 2 Foettinger’s concept – Design and function The Voith fl uid coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with mini-mal mechanical wear

24/09/2014 · The Voith fill-controlled fluid coupling type TPKL is used in belt conveyor tripper drives. It permits separate control of the applied torque at each drive.

Fluid coupling is coupled between drive shaft and driven shaft. The fluid in the coupling absorbs misalignment of both shafts. We played with tops in childhood, rope was wounded around top and left on floor it rotated. The same principle of torque is applied in fluid coupling. Researchmoz added Most

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

Coupling Selection Guide 02 Load Classification by Application 03 Service Factors and Selection 04 Key and Keyway Dimensions 05 Hydrastart Fluid Coupling 06 Operating Principles 07 Delayed Fill 08 ‘Soft’ Starting 09 Hydrastart Selection Chart 10 Coupling Rating Tables 11

The variable fill principle: By controlling the oil flow to the working circuit through a frequency converter, changes occur inside the coupling’s working circuit which alter the coupling’s slip characteristics dramatically softening the ‘start up’. Torque limiting function: Having all the same advantages of fluid couplings, variable fill-drain type fluid couplings build up torque

Fluid Coupling Transmission (Mechanics) Classical

Reliable Speed Control. Geared Variable Speed Couplings

Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger There is oil (orange) in the working and delay chamber of the coupling The motor accelerates the pump wheel (dark grey). In this way an oil circuit is generated in the working chamber of the coupling. The oil is sucked out of the delay chamber flowing into

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

In this paper we explain operation principles of fluid couplings and the structure and features of the fluid coupling for electric motor driven boiler feed pumps as an example of large capaci- ty, high speed fluid couplings used for high pressure pumps.

15/03/2013 · The wear-free power transmission of Voith fluid couplings can be seen in a simple demonstration. The hydrodynamic working principle of torque transmission through fluid flow is illustrated using

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

Experimental Research on Fluid Coupling Flexible Actuator

Fluid Coupling Transmission (Mechanics) Classical

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

Fluid couplings Hydrodynamic power transmission according to the Föttinger principle. 2 Competence meets creativity As a leading manufacturer of high-quality drive and brake components as well as hydraulic components, KTR sup- plies mechanical couplings, clamping sets, torque limiters, measuring systems, hydraulic components and high-power brakes all over the world. With more than 50 years

The variable fill principle: By controlling the oil flow to the working circuit through a frequency converter, changes occur inside the coupling’s working circuit which alter the coupling’s slip characteristics dramatically softening the ‘start up’. Torque limiting function: Having all the same advantages of fluid couplings, variable fill-drain type fluid couplings build up torque

Fluid coupling working principle , Cone Crusher Working Principle Animation Engineering Cone crusher and gyratory crusher work on the same principle. Get More Info; what are the type of couplings for cone crusher. Investigation on appliion of fluid coupling in , common cone crushing terms able to crush any type of The cone crusher has a unique working principle in many what . …

Fixed Machinery: Fluidomat FNCT Fluid Couplings Newly introduced FNCT fluid couplings work on the principle of hydrodynamic power transmission with Fill Control. These are ideal as start-up and acceleration control equipments for large drive motors.

when the fluid coupling is operating transiently with a partially filled working circuit, as will occur during operation at reduced output speed, or during a load acceleration sequence. It therefore continues to be the practice to obtain testbed performance data on one frame size at

Proven a Million Times. Fluid Couplings with Constant Fill.

FLUID COUPLINGS IN HIGHER POWER BELT CONVEYOR

A torque converter is a type of fluid coupling which transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission , the torque converter connects the power source to the load.

Fluid coupling working principle , Cone Crusher Working Principle Animation Engineering Cone crusher and gyratory crusher work on the same principle. Get More Info; what are the type of couplings for cone crusher. Investigation on appliion of fluid coupling in , common cone crushing terms able to crush any type of The cone crusher has a unique working principle in many what . …

According to the principle that the force is equal to the reaction force, the torque of the hydraulic oil on the turbine should equal the torque of the pump wheel on the hydraulic oil, which is the working principle of the hydraulic coupler.

Scoop coupling 1. Prepared by Jishnu V Engineer, BHEL ISG 2. 1. WORKING PRINCIPLE OF A SCOOP COUPLING Scoop coupling consists of two power transmitting elements called Impeller and Runner, both having a large number of straight radial vanes In a conveyor system the prime mover (motor) drives the impeller.

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

Scoop coupling pdf WordPress.com

Fluid coupling.pdf Transmission (Mechanics) Pump

Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger There is oil (orange) in the working and delay chamber of the coupling The motor accelerates the pump wheel (dark grey). In this way an oil circuit is generated in the working chamber of the coupling. The oil is sucked out of the delay chamber flowing into

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

View Fluid Coupling Working Principle PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. Share yours for free!

A fluid coupling is a hydrodynamic device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch . It also has widespread application in marine and industrial machine drives, where variable speed operation and/or controlled start-up without shock loading of the power transmission system is essential.

fluidomat scoop coupling pdf Fluid coupling are supplied with thermal safety device as fusible plug for.The Pembril SDFC Fluid Coupling when used in conjunction with a. possible to employ a smaller motor because the Fluid Coupling allow the Motor to run.Fluid Coupling.

A fluid coupling is a hydrokinetic transmission unit comprised of three main elements: 1. Driving impeller (pump) mounted on the input shaft. 2. Driven impeller (turbine) mounted on the output shaft. 3. Cover, flanged to the output impeller, with an oil-tight seal. The first two elements can work both as pump and/or turbine. The impellers perform like a centrifugal pump and a hydraulic turbine

15/03/2013 · The wear-free power transmission of Voith fluid couplings can be seen in a simple demonstration. The hydrodynamic working principle of torque transmission through fluid flow is illustrated using

direct working principle, where, for instance, power is transmitted via mechanical couplings, hydrodynamic couplings transmit power by means of a fl uid. Since torque transmission is realized via a fl uid there is almost no wear in comparison to the direct working principle. Inner drive Figure 3 depicts a fl uid coupling at standstill, during start-up and at nominal operation. During start

In this paper we explain operation principles of fluid couplings and the structure and features of the fluid coupling for electric motor driven boiler feed pumps as an example of large capaci- ty, high speed fluid couplings used for high pressure pumps.

coupling, coupling eccentricity to the shaft fit, bent input shaft, fluid coupling cocked on the shaft fit, coupling hub eccentricity, long/short keys, etc. Running unloaded, the typical slip of the fluid …

2 Construction, Working, Operation and Maintenance of Fluid Couplings www.practicalmaintenance.net Fluid Couplings Fluid couplings or hydraulic couplings work on the hydrodynamic principle.

The fill-controlled fluid coupling type TPW is predominantly used in drives for separators and centrifuges. The fluid coupling supported by the motor is mounted in …

The fluid coupling slip characteristics spreads the absorption of the impact over a period of time, reducing stress on the components and therefore, protecting your machinery.

Fluidomat Variable Speed Fluid Couplings for Fixed Speed

Fluid Coupling Transmission (Mechanics) Classical

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

A fluid coupling is a hydrodynamic device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch . It also has widespread application in marine and industrial machine drives, where variable speed operation and/or controlled start-up without shock loading of the power transmission system is essential.

The operation of a fluid coupling is based on hydrokinetic principles and requires that the output speed be less than the input . This difference in speed is called slip .

assembly, communicating with the working circuit by means of calibrated nozzles and retaining part of the fluid when the fluid Coupling stops running. At motor switch-on, only the fluid in the work circuit is active and the torque developed is low.

fluidomat scoop coupling pdf Fluid coupling are supplied with thermal safety device as fusible plug for.The Pembril SDFC Fluid Coupling when used in conjunction with a. possible to employ a smaller motor because the Fluid Coupling allow the Motor to run.Fluid Coupling.

Reversible Fluid Coupling – bulk-online. Apr 14, 2009· Dear Sirs, By mistake I used FLUID COUPLING in a conveyor which is reversible in nature I am not sure about the use of fluid coupling in a reversible conveyor It is a trction type fluid coupling

ALPHA FLUID COUPLING JIS System (m) Sdn Bhd

Coal Mining Equipment Vibration Analysis Sept 3 2014

COUPLING DESCRIPTION AND WORKING PRINCIPLE ROTOFLUID — , ˘ ˝ ˇ ˛ . The ROTOFLUID fluid coupling is a transmission

Currently, Naismith has virtually every size of fixed speed Fluidomat fluid coupling in their warehouse in Melbourne, including shaft mounted, radially displaceable, pulley design and steel bodied for the underground mining requirements.

when the fluid coupling is operating transiently with a partially filled working circuit, as will occur during operation at reduced output speed, or during a load acceleration sequence. It therefore continues to be the practice to obtain testbed performance data on one frame size at

2 Construction, Working, Operation and Maintenance of Fluid Couplings www.practicalmaintenance.net Fluid Couplings Fluid couplings or hydraulic couplings work on the hydrodynamic principle.

Working Principle The working process of the prototype is as follows. The piezoelectric oscillator driven by alternating voltage provides reciprocating bending deformation. The energy through the incompressible fluid in the chamber drives silicone diaphragm moving up and so that forms the ability of displacement output. In the situation that the silicone diaphragm is working at the resonant

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

24/09/2014 · The Voith fill-controlled fluid coupling type TPKL is used in belt conveyor tripper drives. It permits separate control of the applied torque at each drive.

Experimental Research on Fluid Coupling Flexible Actuator

Fluid Coupling Transmission (Mechanics) Classical

TURBOSTART HYDRODYNAMIC COUPLINGS New Turbostart s.r.l. was born in 1958, its corporate purpose is the production and sale of mechanical and hydraulic drives; the company has always been renowned for their new products reliability and professional service offered to clientele. It is a compact structure , efficient and always ready to solve the most varied problems of customers, succeding in

Currently, Naismith has virtually every size of fixed speed Fluidomat fluid coupling in their warehouse in Melbourne, including shaft mounted, radially displaceable, pulley design and steel bodied for the underground mining requirements.

The operation of a fluid coupling is based on hydrokinetic principles and requires that the output speed be less than the input . This difference in speed is called slip .

15/03/2013 · The wear-free power transmission of Voith fluid couplings can be seen in a simple demonstration. The hydrodynamic working principle of torque transmission through fluid flow is illustrated using

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the drive’s characteristics during periods of high

Hydrastart Couplings renold.com

Fluid couplings Morskate Aandrijvingen

fluid means a particular challenge, especially as to the materials used and the little necessities around a hydrodynamic coupling. But for the user it is the best.

A fluid coupling is a hydrokinetic transmission unit comprised of three main elements: 1. Driving impeller (pump) mounted on the input shaft. 2. Driven impeller (turbine) mounted on the output shaft. 3. Cover, flanged to the output impeller, with an oil-tight seal. The first two elements can work both as pump and/or turbine. The impellers perform like a centrifugal pump and a hydraulic turbine

fluidomat scoop coupling pdf Fluid coupling are supplied with thermal safety device as fusible plug for.The Pembril SDFC Fluid Coupling when used in conjunction with a. possible to employ a smaller motor because the Fluid Coupling allow the Motor to run.Fluid Coupling.

Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger There is oil (orange) in the working and delay chamber of the coupling The motor accelerates the pump wheel (dark grey). In this way an oil circuit is generated in the working chamber of the coupling. The oil is sucked out of the delay chamber flowing into

In this paper we explain operation principles of fluid couplings and the structure and features of the fluid coupling for electric motor driven boiler feed pumps as an example of large capaci- ty, high speed fluid couplings used for high pressure pumps.

Currently, Naismith has virtually every size of fixed speed Fluidomat fluid coupling in their warehouse in Melbourne, including shaft mounted, radially displaceable, pulley design and steel bodied for the underground mining requirements.

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

FLUID COUPLING WORKING PRINCIPLE by. Harikesh Divedi on. February 14, 2015 in Engineering Maintenance. In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid couplin… In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid coupling? Fluid coupling is also known as

COUPLING DESCRIPTION AND WORKING PRINCIPLE ROTOFLUID — , ˘ ˝ ˇ ˛ . The ROTOFLUID fluid coupling is a transmission

constant fill coupling is a hydrodynamic fluid coupling working on the Fottinger principle. The torque developed by the electric The torque developed by the electric motor is converted by the primary side of the coupling that is directly connected to the motor shaft, into kinetic energy.

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

Reliable Speed Control. Geared Variable Speed Couplings

Fluid Couplings chainanddrives.com.au

fluid coupling working principle in crusher. Constant speed – Fluid Coupling. Fluidomat has supplied their fluid couplings for more than 500 projects in India and Abroad in all sectors of industries,Fluid coupling working principle,Fluid

TURBOSTART HYDRODYNAMIC COUPLINGS New Turbostart s.r.l. was born in 1958, its corporate purpose is the production and sale of mechanical and hydraulic drives; the company has always been renowned for their new products reliability and professional service offered to clientele. It is a compact structure , efficient and always ready to solve the most varied problems of customers, succeding in

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

• Principle of fluid coupling Impeller Runner . As we everybody aware that pump is t transforming f i kikinetic ti energy off iimpeller ll into i t pressure head h d in i fluid and turbine in turn absorb the pressure head and produce kinetic energy of runner. Now the point comes into play on the selection of working fluid for smooth running of pump and turbine placed in close vicinity in a

A fluid coupling is a hydrodynamic device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch . It also has widespread application in marine and industrial machine drives, where variable speed operation and/or controlled start-up without shock loading of the power transmission system is essential.

Fluid Couplings with Constant Fill. 2 Foettinger’s concept – Design and function The Voith fl uid coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with mini-mal mechanical wear

Fluid coupling is coupled between drive shaft and driven shaft. The fluid in the coupling absorbs misalignment of both shafts. We played with tops in childhood, rope was wounded around top and left on floor it rotated. The same principle of torque is applied in fluid coupling. Researchmoz added Most

constant fill coupling is a hydrodynamic fluid coupling working on the Fottinger principle. The torque developed by the electric The torque developed by the electric motor is converted by the primary side of the coupling that is directly connected to the motor shaft, into kinetic energy.

coupling, coupling eccentricity to the shaft fit, bent input shaft, fluid coupling cocked on the shaft fit, coupling hub eccentricity, long/short keys, etc. Running unloaded, the typical slip of the fluid …

Fluid Couplings Flexible Couplings Fluidomat

INSTALLATION AND MAINTENANCE MANUAL dbes.co.id

COUPLING DESCRIPTION AND WORKING PRINCIPLE ROTOFLUID — , ˘ ˝ ˇ ˛ . The ROTOFLUID fluid coupling is a transmission

Reversible Fluid Coupling – bulk-online. Apr 14, 2009· Dear Sirs, By mistake I used FLUID COUPLING in a conveyor which is reversible in nature I am not sure about the use of fluid coupling in a reversible conveyor It is a trction type fluid coupling

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

2 Construction, Working, Operation and Maintenance of Fluid Couplings www.practicalmaintenance.net Fluid Couplings Fluid couplings or hydraulic couplings work on the hydrodynamic principle.

Chain & Drives can supply all types of market-leading fluid couplings, including: Transfluid; Flender; Fluidomat; Westcar; Siemens; Turbo Start; Voith; Fluid Couplings comprise of . Driving impeller (pump) mounted on the input shaft. Driven impeller (turbine) mounted on the output shaft. Cover, flanged to the outer impeller, with an oil-tight seal. The first two elements can work both as pump

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

FLUID COUPLING •Fluid coupling is a device which is used to transmit torque from engine to gear box with fluid as working torque from engine to gear box with fluid as working medium. •The purpose of fluid coupling is to act as flexible power transmitting coupling . Construction Details of Fluid Coupling Fluid travels either in a rotary or vortex motion . Principle of fluid coupling

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the drive’s characteristics during periods of high

Proven a Million Times. Fluid Couplings with Constant Fill.

Voith Turbo Fluid Couplings with Constant Fill Masino

dynamic coupling based on Foettinger’s Principle. Its main com-ponents are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Output is achieved with minimal me-chanical wear as there is no mechani-cal contact between power-transmit-ting parts. The coupling contains a constant quantity of operating fluid

Chain & Drives can supply all types of market-leading fluid couplings, including: Transfluid; Flender; Fluidomat; Westcar; Siemens; Turbo Start; Voith; Fluid Couplings comprise of . Driving impeller (pump) mounted on the input shaft. Driven impeller (turbine) mounted on the output shaft. Cover, flanged to the outer impeller, with an oil-tight seal. The first two elements can work both as pump

when the fluid coupling is operating transiently with a partially filled working circuit, as will occur during operation at reduced output speed, or during a load acceleration sequence. It therefore continues to be the practice to obtain testbed performance data on one frame size at

10/11/2010 · 2018 Latest New Technology Electric Vehicle Motor_Motor Equipment Supply From China – Duration: 9:22. SMT Winding Equipment 248,681 views

Fill-controlled Fluid Couplings. 2 Start-up Components We are the experts in constant-fi ll and fi ll-controlled fl uid couplings at Voith Turbo. Voith Turbo, the specialist for hydro-dynamic drive, coupling and braking systems for road, rail and industrial applications, as well as for ship propulsion systems, is a Group Division of Voith GmbH. Voith is one of the largest family-owned

constant fill coupling is a hydrodynamic fluid coupling working on the Fottinger principle. The torque developed by the electric The torque developed by the electric motor is converted by the primary side of the coupling that is directly connected to the motor shaft, into kinetic energy.

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

Fluid couplings for Thermal and Nuclear Power Generation ,Steel and Metal,Coal Lignite and Ore Mining,Fertilizers and Chemicals,Harbour Handling,fluid coupling,constant fill,constant speed,Variable Speed Fluid Couplings,Fluid Couplings for wood chippers,Fluid Couplings for Stone Crushers

FLUID COUPLING WORKING PRINCIPLE by. Harikesh Divedi on. February 14, 2015 in Engineering Maintenance. In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid couplin… In this post, we will try to understand the basic concept of “Fluid coupling”. First, let us understand what is fluid coupling? Fluid coupling is also known as

Working Principle The working process of the prototype is as follows. The piezoelectric oscillator driven by alternating voltage provides reciprocating bending deformation. The energy through the incompressible fluid in the chamber drives silicone diaphragm moving up and so that forms the ability of displacement output. In the situation that the silicone diaphragm is working at the resonant

COUPLING DESCRIPTION AND WORKING PRINCIPLE ROTOFLUID — , ˘ ˝ ˇ ˛ . The ROTOFLUID fluid coupling is a transmission

Fluid coupling working principle , Cone Crusher Working Principle Animation Engineering Cone crusher and gyratory crusher work on the same principle. Get More Info; what are the type of couplings for cone crusher. Investigation on appliion of fluid coupling in , common cone crushing terms able to crush any type of The cone crusher has a unique working principle in many what . …

fluidomat scoop coupling pdf Fluid coupling are supplied with thermal safety device as fusible plug for.The Pembril SDFC Fluid Coupling when used in conjunction with a. possible to employ a smaller motor because the Fluid Coupling allow the Motor to run.Fluid Coupling.

4 Föttinger principle – the Föttinger coupling Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger

The fluid coupling originates from the work of Hermann Föttinger, who was the chief designer at the AG Vulcan Works in Stettin. His patents from 1905 covered both fluid couplings and torque converters.

Hydrastart Couplings renold.com

INSTALLATION AND MAINTENANCE MANUAL dbes.co.id

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the drive’s characteristics during periods of high

Explain the working principle of sliding mesh gear box draw the suitable sketch. 2.Explain the working principle of constant mesh gear box draw the suitable sketch. MAY/JUNE2013.

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the

Fluid couplings for Thermal and Nuclear Power Generation ,Steel and Metal,Coal Lignite and Ore Mining,Fertilizers and Chemicals,Harbour Handling,fluid coupling,constant fill,constant speed,Variable Speed Fluid Couplings,Fluid Couplings for wood chippers,Fluid Couplings for Stone Crushers

COUPLING DESCRIPTION AND WORKING PRINCIPLE ROTOFLUID — , ˘ ˝ ˇ ˛ . The ROTOFLUID fluid coupling is a transmission

ating fluid in the working circuit is accelerated via the pump wheel. The circulatory flow created in this The Voith Turbo Coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with

According to the principle that the force is equal to the reaction force, the torque of the hydraulic oil on the turbine should equal the torque of the pump wheel on the hydraulic oil, which is the working principle of the hydraulic coupler.

dynamic coupling based on Foettinger’s Principle. Its main com-ponents are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Output is achieved with minimal me-chanical wear as there is no mechani-cal contact between power-transmit-ting parts. The coupling contains a constant quantity of operating fluid

Fluid couplings with delay fill chamber OPERATING PRINCIPLES AND FEATURES OF ROTOFLUID COUPLING The ROTOFLUID fluid coupling is designed to provide your plant with optimum reliability and durability. It is fitted between the motor (drive) and machine (driven component). The ROTOFLUID fluid coupling comprises basically two impellers, with radial blades, opposed to …

10/11/2010 · 2018 Latest New Technology Electric Vehicle Motor_Motor Equipment Supply From China – Duration: 9:22. SMT Winding Equipment 248,681 views

A fluid coupling is a hydrokinetic transmission unit comprised of three main elements: 1. Driving impeller (pump) mounted on the input shaft. 2. Driven impeller (turbine) mounted on the output shaft. 3. Cover, flanged to the output impeller, with an oil-tight seal. The first two elements can work both as pump and/or turbine. The impellers perform like a centrifugal pump and a hydraulic turbine

24/09/2014 · The Voith fill-controlled fluid coupling type TPKL is used in belt conveyor tripper drives. It permits separate control of the applied torque at each drive.

Fluidomat Variable Speed Fluid Couplings for Fixed Speed

TURBOSTART HYDRODYNAMIC COUPLINGS Chain and Drives

dynamic coupling based on Foettinger’s Principle. Its main com-ponents are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Output is achieved with minimal me-chanical wear as there is no mechani-cal contact between power-transmit-ting parts. The coupling contains a constant quantity of operating fluid

COUPLING DESCRIPTION AND WORKING PRINCIPLE ROTOFLUID — , ˘ ˝ ˇ ˛ . The ROTOFLUID fluid coupling is a transmission

In this paper we explain operation principles of fluid couplings and the structure and features of the fluid coupling for electric motor driven boiler feed pumps as an example of large capaci- ty, high speed fluid couplings used for high pressure pumps.

Fluid Couplings with Constant Fill. 2 Foettinger’s concept – Design and function The Voith fl uid coupling is a hydrodynamic coupling based on Foettinger’s Principle. Its main components are two bladed wheels – a pump wheel and a turbine wheel – as well as an outer shell. Both wheels are positioned relative to each other. Power transmission is achieved with mini-mal mechanical wear

Fixed Machinery: Fluidomat FNCT Fluid Couplings Newly introduced FNCT fluid couplings work on the principle of hydrodynamic power transmission with Fill Control. These are ideal as start-up and acceleration control equipments for large drive motors.

direct working principle, where, for instance, power is transmitted via mechanical couplings, hydrodynamic couplings transmit power by means of a fl uid. Since torque transmission is realized via a fl uid there is almost no wear in comparison to the direct working principle. Inner drive Figure 3 depicts a fl uid coupling at standstill, during start-up and at nominal operation. During start

constant fill coupling is a hydrodynamic fluid coupling working on the Fottinger principle. The torque developed by the electric The torque developed by the electric motor is converted by the primary side of the coupling that is directly connected to the motor shaft, into kinetic energy.

A fluid coupling is a two element drive that is incapable of multiplying torque, while a torque converter has at least one extra element—the stator—which alters the

2 Construction, Working, Operation and Maintenance of Fluid Couplings www.practicalmaintenance.net Fluid Couplings Fluid couplings or hydraulic couplings work on the hydrodynamic principle.

Originally the operating principle of the fluid coupling is based on the hydrodynamic torque converter patented by Hermann Föttinger There is oil (orange) in the working and delay chamber of the coupling The motor accelerates the pump wheel (dark grey). In this way an oil circuit is generated in the working chamber of the coupling. The oil is sucked out of the delay chamber flowing into